Introduction to White Cement

White cement is a special type of Portland cement known for its smooth texture and bright white appearance. Unlike ordinary grey cement, it is produced from raw materials that contain very little iron oxide and manganese oxide, giving it a clean, luminous finish.

Because of its attractive color and ability to create smooth, decorative surfaces, white it is widely used in architectural and finishing works such as floor tiles, wall coatings, and precast panels. It has become a preferred choice for projects where appearance matters as much as strength.

In this article, you will learn about what white cement is, its properties, advantages and disadvantages, uses, tips for proper application, a comparison with ordinary Portland cement (OPC), the top brands of white cement in India, and answers to frequently asked questions, so read the full article. Let’s start:

What is White Cement?

It is a type of Portland cement that is specially manufactured to achieve a bright white color instead of the usual grey. This color difference is mainly due to the selection of raw materials. It is produced using limestone and clay that have very low amounts of iron oxide and manganese oxide — the compounds that usually give ordinary cement its grey tone.

The manufacturing process also involves controlled burning in special kilns at high temperatures. This ensures uniform whiteness and a smoother texture. Although the chemical composition of white cement is similar to ordinary Portland cement (OPC), its cost is higher because of the use of purified raw materials and more precise production methods.

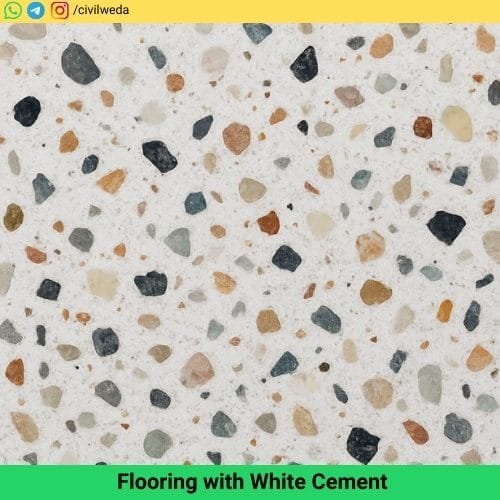

Due to its attractive appearance and fine finish, white cement is often chosen for decorative architectural works such as terrazzo floors, wall claddings, precast panels, and ornamental designs where color and aesthetics play an important role.

Properties of White Cement

White cement has several unique features that make it different from ordinary grey cement. These properties influence its performance, appearance, and the type of applications for which it is most suitable.

Bright White Color

The most distinguishing property of this cement is its luminous white color. This is achieved by selecting raw materials such as limestone and china clay that contain very small amounts of iron oxide and manganese oxide, the compounds responsible for the grey shade of ordinary cement. As a result, the finished product has a clean, bright appearance that enhances the aesthetics of decorative walls, monuments, sculptures, and architectural facades.

Smooth and Fine Texture

White cement is ground more finely than ordinary Portland cement. This fine grinding produces a silky, smooth texture that helps in creating uniform coatings and a flawless surface finish. Such smoothness is especially useful in decorative works, ornamental panels, terrazzo floors, and other applications that require precision and high-quality appearance.

Moderate Compressive Strength

While white cement is strong enough for finishing and decorative purposes, it typically offers slightly lower compressive strength than OPC cement. Its strength after 28 days of curing is usually in the range of 35–40 MPa, which is adequate for non-structural applications but not ideal for load-bearing elements such as beams, columns, and foundations. For these heavy structural components, OPC cement is generally preferred.

Excellent Workability and Mixing Ability

Due to its fine texture and uniform particle size, white cement has very good workability. It mixes easily with water and with color pigments, allowing craftsmen to produce colorful decorative finishes and intricate designs. This property makes it a preferred choice for terrazzo flooring, precast elements, and artistic detailing in architectural projects.

Aesthetic Durability

One of the key advantages of white cement is its ability to retain its brightness and smooth appearance for a long time. When properly applied and maintained, it resists weathering, fading, and staining, which is particularly valuable for monuments, facades, and decorative surfaces that must remain attractive over time.

Reflective Surface

Another important property is its higher reflectivity compared to OPC. The bright white surface reflects more sunlight and heat, which can help reduce heat absorption in buildings and outdoor structures. This makes white cement an excellent choice for exterior walls, pavements, and architectural elements in regions with hot climates.

These properties collectively make white cement a specialized material for aesthetic and decorative construction purposes. While it delivers a superior appearance and durable finish, it is not intended to replace ordinary cement in structural works.

Advantages of White Cement

White cement is widely valued in the construction industry for its special qualities that make it stand out from ordinary grey cement. These advantages explain why it is often chosen for decorative and finishing applications.

Attractive Appearance

One of the most significant advantages of white cement is its bright, clean appearance. The luminous white color makes it an excellent choice for architectural finishes, decorative coatings, monuments, and sculptures. It enhances the visual appeal of surfaces and helps create elegant, modern designs that are difficult to achieve with grey cement.

Because of its fine texture and high purity, white cement produces smooth, even surfaces with a refined finish. It allows builders and designers to achieve a flawless look for wall claddings, ceilings, precast elements, and artistic features. This quality is particularly important in projects where aesthetics and surface detailing matter.

Versatility in Decorative Applications

White cement can be used in a wide range of decorative and artistic works. It blends well with pigments, which makes it possible to create colored finishes for floors, wall coatings, tiles, and terrazzo designs. This versatility makes it a preferred material for projects that require both durability and visual creativity.

Better Light Reflectivity

The bright surface of white cement reflects more light compared to grey cement. This reflective property improves the brightness of interiors and exteriors, reduces the need for artificial lighting during the day, and helps create a pleasant environment in public spaces, monuments, and religious buildings.

Resistance to Weathering and Fading

White cement retains its brightness and fresh look for a longer period when properly applied and maintained. It resists moderate weathering and does not fade easily under sunlight, which makes it a reliable material for outdoor architectural features such as facades, decorative pavements, and monuments.

Improved Workability with Pigments

Thanks to its smooth and fine texture, white cement mixes easily with water and pigments, resulting in uniform color distribution and consistent finishes. This property is especially useful for producing colored tiles, artistic patterns in terrazzo flooring, and intricate ornamental designs.

These advantages make white cement a preferred material for builders, architects, and designers who aim to combine strength with visual appeal. Its ability to create bright, smooth, and long-lasting decorative finishes distinguishes it from ordinary cement, especially in projects where aesthetics are a primary consideration.

Disadvantages of White Cement

Although white cement offers many benefits in terms of appearance and decorative quality, it also has some limitations that must be considered before choosing it for a construction project.

Higher Cost

The production of white cement involves the use of high-purity raw materials and special manufacturing processes, which makes it more expensive than ordinary Portland cement. For large-scale structural works, the higher cost can significantly increase the overall project budget. Therefore, it is usually preferred only for decorative or finishing purposes rather than for entire structural components.

Moderate Strength for Structural Works

White cement generally has slightly lower compressive strength compared to grey cement. While it performs well in finishing works and decorative elements, it is not the best choice for load-bearing structures such as beams, columns, or heavy foundations. Using it in such applications may compromise structural performance and increase construction costs unnecessarily.

Limited Availability

White cement is not as widely available as grey cement, especially in rural or remote areas. This limited supply can sometimes cause delays in construction schedules or lead to higher transportation costs. Builders often have to plan to ensure they have enough stock for their projects.

Prone to Staining and Dirt

The bright white surface of this cement, while visually appealing, is also more susceptible to stains, dust, and marks. Any exposure to dirt or moisture can reduce its brightness over time. Therefore, surfaces finished with white cement require regular cleaning and proper maintenance to retain their elegant appearance.

Requires Skilled Application

Achieving a smooth and flawless finish with white cement often demands skilled workers. Inexperienced application can lead to uneven surfaces, patches, or even wastage of material. This can increase labor costs and reduce the quality of the final finish if not handled by professionals.

These drawbacks highlight that white cement is not suitable for all construction purposes. While it excels in providing an attractive and durable finish for decorative works, it may not be the most practical or economical choice for structural components or for projects where maintenance is a concern.

Comparison between White Cement and Ordinary Portland Cement (OPC)

White cement and ordinary Portland cement (OPC) serve different purposes in construction. The table below highlights their key differences so that builders, students, and professionals can quickly understand where each type is best suited.

| Feature | White Cement | OPC (Grey Cement) |

|---|---|---|

| Color | Bright white; ideal for decorative works. | Grey; mostly used in structural works. |

| Strength | Moderate (≈35–40 MPa), good for finishing. | Higher (more than 43 MPa), suitable for heavy loads. |

| Cost | More expensive due to special materials. | More economical and widely used. |

| Availability | Limited in many regions. | Easily available everywhere. |

| Applications | Decorative finishes, precast panels, terrazzo, monuments. | Foundations, beams, columns, bridges, other structural works. |

Tips for Using White Cement Effectively

To achieve the best results with white cement, it is important to handle it carefully during mixing, application, and maintenance. Following certain practices ensures that the finished surface retains its bright color and smooth finish for a long time.

Use Clean Raw Materials

White cement owes its brightness to its purity, which can be compromised if mixed with impure sand or water. Always use clean, fine sand and potable water free from organic matter, salts, or other impurities. Contaminated materials can cause stains, discoloration, or weaken the finished surface.

Avoid Mixing with Grey Cement

Although it might be tempting to reduce costs by mixing white cement with grey cement, doing so usually dulls the bright white appearance and can affect the quality of decorative finishes. For surfaces where appearance is important, use white cement on its own or with approved pigments.

Handle Pigments Carefully

When coloring white cement for terrazzo floors or decorative coatings, ensure that the pigments are of high quality and evenly mixed. Uneven mixing can lead to patchy surfaces or fading over time. Adding pigments gradually while mixing helps achieve a consistent color.

Apply to Clean and Even Surfaces

For a flawless finish, the surface to be coated should be free from dust, grease, or loose particles. Uneven or dirty surfaces can lead to poor adhesion and compromise the brightness and smoothness of the final layer.

Control Water–Cement Ratio

Using too much water can weaken the mix and lead to cracks or uneven color. Maintain the recommended water–cement ratio to ensure a durable, smooth, and uniform finish. A slightly lower water content usually provides a denser and more long-lasting surface.

Protect the Finished Surface

After application, protect the fresh surface from dust, stains, and excessive moisture during the initial curing period. Proper curing is essential for achieving the desired strength and finish. For exterior applications, regular cleaning and maintenance help preserve the brightness and appearance over time.

By following these tips, builders, architects, and even homeowners can get the most out of white cement, ensuring that its attractive finish, durability, and long-lasting brightness are maintained.

Top Brands of White Cement in India

White cement is produced by several leading manufacturers in India. These brands are known for consistent quality and wide availability across the country.

1. JK White Cement

One of the most popular brands in India, JK Cement is well-known for its brightness, smooth finish, and reliable quality. It is widely used for wall finishes, precast elements, and decorative applications.

👉 Visit JKCement to explore more

2. Birla White Cement

Birla Cement is another top brand, recognized for its high whiteness and durability. It is commonly used in floorings, wall finishes, and artistic decorative works.

👉 Visit Birla Cement to explore more

Disclaimer: The brands mentioned here are provided only for educational and informational purposes. Civil Weda is not promoting or endorsing any specific brand. Readers should choose products based on their project needs and local availability.

Read more Civil Engg topics

- Chlorination of water

- Per Capita Water Demand

- Pile foundation

- Drip Irrigation

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Bitumen concrete

Conclusion

White cement is an excellent choice for projects that prioritize appearance and fine detailing, offering a smooth, bright, and elegant finish. However, it is less suitable for heavy structural works due to its moderate strength and higher cost. By understanding both its advantages and limitations, builders, students, and professionals can use it wisely to achieve durable and attractive results in decorative and finishing applications.

FAQs on White Cement

1. Is white cement as strong as grey cement?

No, it has slightly lower strength, suitable mainly for decorative works.

2. Can white cement be used for structural construction?

No, it’s mostly used for finishing and decorative purposes.

3. Why is white cement more expensive than grey cement?

It’s made from high-purity raw materials and a specialized manufacturing process.

4. Does white cement need special curing?

No, it requires the same standard curing as ordinary cement.

5. Can pigments be added to white cement for colored finishes?

Yes, it mixes well with compatible pigments for decorative designs.

6. How can the bright appearance of white cement be maintained?

By keeping surfaces clean, protected from dust, moisture, and stains.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the White cement in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀