When we talk about concrete or mortar, sand is one of the most important ingredients. Cement and coarse aggregates get all the attention, but without sand, the mix cannot achieve good workability or strength. There’s one interesting property of sand that often creates confusion on construction sites – Bulking of Sand.

If you have ever noticed that moist sand looks like it occupies more space than dry or fully wet sand, that is exactly what bulking means. Ignoring this effect can lead to serious mistakes in proportioning.

What is the Bulking of Sand?

Bulking of sand is the increase in volume of sand due to the presence of a thin film of moisture around its particles.

- Dry sand → No bulking

- Moist sand → Volume increases (Bulking occurs)

- Fully saturated sand → Volume returns to normal

In simple words, if you take a bucket of dry sand and sprinkle just a little water, it will appear as if the sand has increased in volume. That is bulking.

Why does Happen buikibg in sand?

Bulking of sand occurs because of the surface tension of water. When sand gets wet, a thin layer of water forms around each sand grain, causing the grains to stick together in clumps. These clumps create small gaps or voids between the particles, so the sand takes up more space than when it is dry.

The amount of bulking depends on the water content in the sand. Slightly damp sand (around 4–6% moisture) shows maximum bulking. If more water is added, it fills the gaps between grains, and the sand starts to settle back to its normal volume.

The type of sand also matters. Fine sand or sand with uneven particle sizes shows more bulking, while coarse, medium, and well-graded sand shows less. Even environmental factors, like humidity, can affect bulking in stored sand.

In short:

- At low moisture content (about 4–6%), a thin water film forms around each particle.

- This water film pushes the particles slightly apart.

- Sand grains cannot pack closely, increasing the overall volume.

- Once the sand is fully saturated, water fills the voids, the film disappears, and the sand returns to its true volume.

Test for Bulking of Sand:

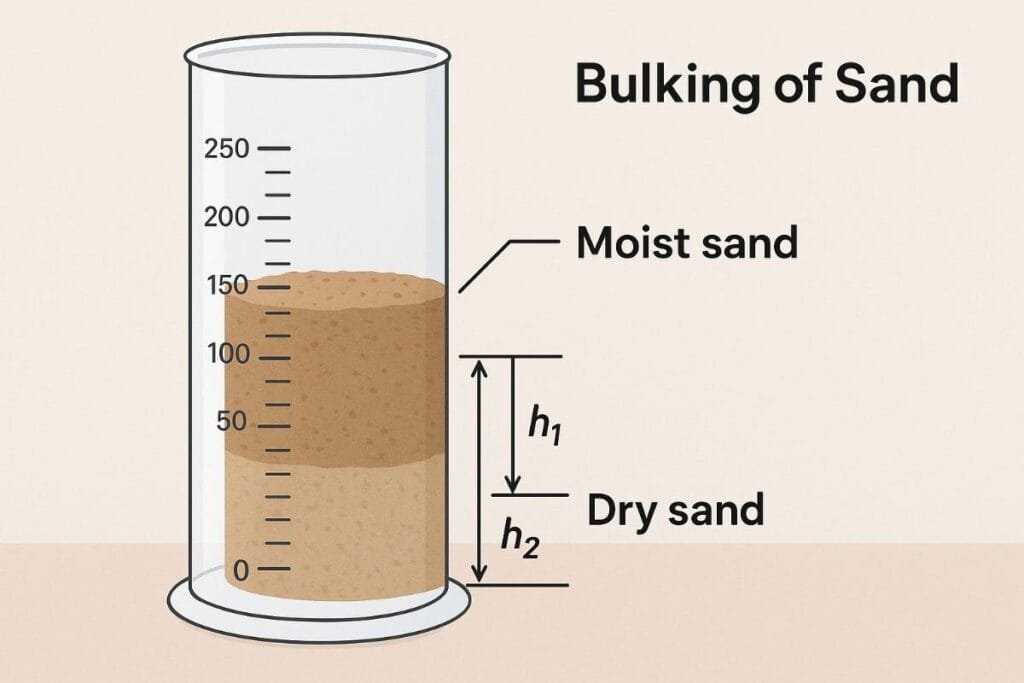

The bulking of sand can be checked easily on-site without any laboratory equipment. A simple graduated cylinder test is enough to understand how much sand is bulking due to moisture.

Materials Needed:

- A graduated measuring cylinder as shown in the figure-

- A sample of moist sand (taken directly from the construction site)

- Clean water

Step-by-Step Procedure:

- Filling the Cylinder

Fill the cylinder about two-thirds with moist sand.

Example: In a 500 ml cylinder, fill around 300–350 ml with sand. - Note the Initial Height (h1)

Carefully record the level of sand in the cylinder.- Suppose the initial height is 260 ml.

- Add Water and Stir

Slowly pour water into the cylinder and stir the sand gently with a rod or stick.- As water fills the voids, it removes the thin moisture film and trapped air, allowing the sand grains to settle.

- Note the Final Height (h2)

Once the sand has settled completely, record the new level.- Suppose the final height is 200 ml.

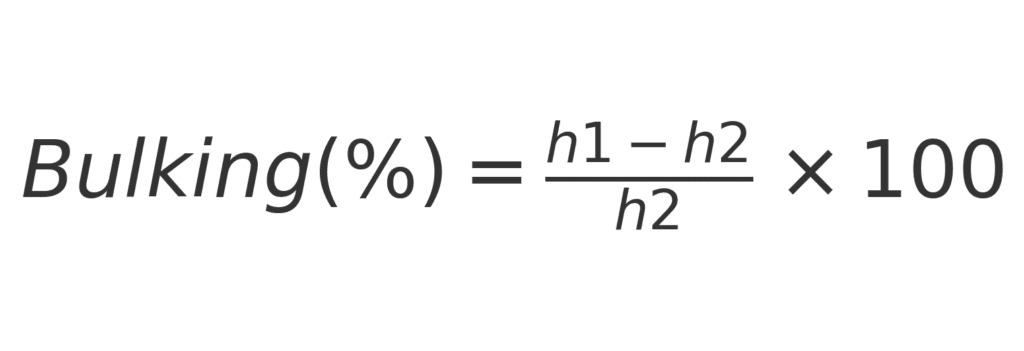

The formula used in the buckling of sand

Factors Affecting Bulking:

- Moisture Content:

Slightly damp sand shows maximum bulking (4–6%). Too little water has little effect, and too much water makes the sand settle. - Type of Sand:

Fine sand bulks more than coarse sand. - Grain Shape:

Rounded grains bulk less; angular grains bulk more. - Grain Size Distribution:

Uniform sand bulks more; well-graded sand bulks less. - Humidity and Storage Conditions:

Sand stored in humid areas may already contain moisture, affecting bulking. - Compaction:

Loose sand bulks more compared to compacted sand.

Summary:

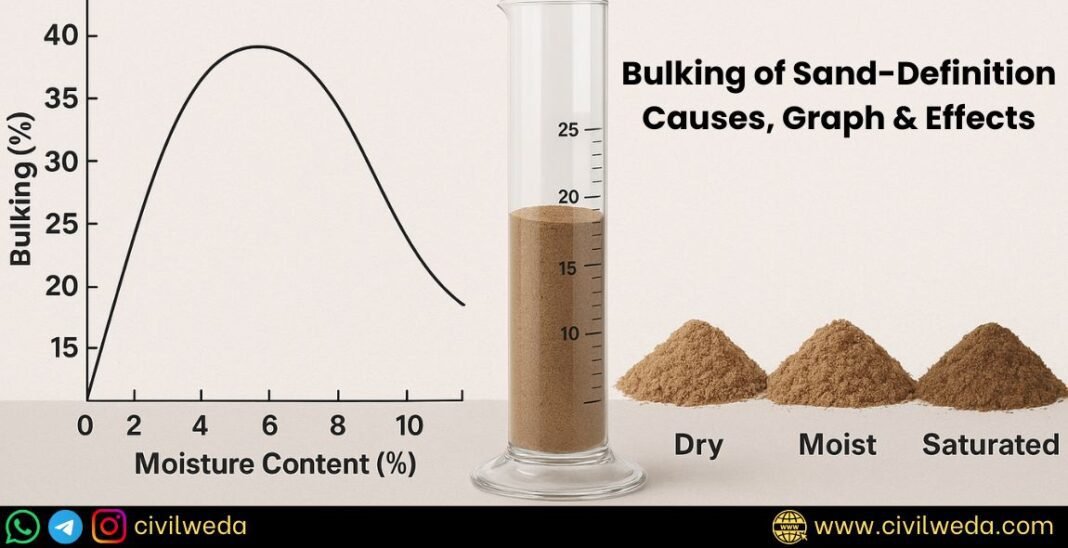

- Maximum bulking occurs at about 4–6% water content.

- Fine sand can bulk up to 35–40%.

- Coarse sand bulks only 15–20%.

- Angular particles show more bulking compared to rounded ones.

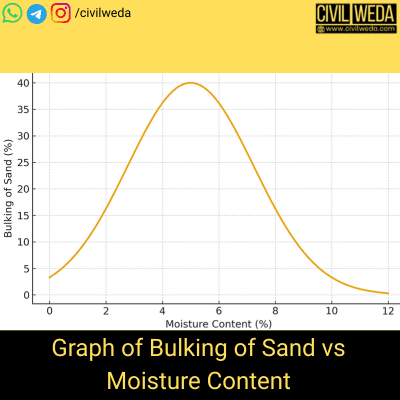

Bulking of Sand Graph

The relation between moisture content and bulking resembles a bell-shaped curve, as shown in the figure:

- 0% moisture → No bulking

- 4–6% moisture → Maximum bulking

- 8–10% moisture → Bulking decreases

Effect of Bulking of Sand in Construction:

- Incorrect Proportion in Concrete/Mortar: Extra volume due to bulking can lead to a higher sand-to-cement ratio, weakening the mix.

- Reduced Workability: Excess sand makes the mix stiff and hard to work with.

- Material Wastage: More cement and water may be needed to maintain the correct mix.

- Structural Weakness: Wrong proportions can cause cracks, honeycombing, or premature failure.

- Measurement Errors: Measuring by volume without accounting for bulking can overestimate the sand required.

Precautions to Avoid Errors Due to Bulking of sand:

- Use Dry Sand: Oven-dried or air-dried sand ensures accurate measurement.

- Adjust for Moisture Content: Reduce measured volume for damp sand (usually 20–30% for slightly wet sand).

- Measure by Weight Instead of Volume: Weight measurement avoids errors caused by bulking.

- Proper Storage of Sand: Keep sand covered to prevent moisture absorption.

- Regularly Check Moisture Levels: Adjust mix proportions if necessary.

- Avoid Excess Water in Mix: Maintain the correct water-cement ratio.

- Use Standard Tables or Correction Charts: Quick adjustment of sand volume based on moisture content.

Real-Life Example of Bukling of sand:

Bulking of sand occurs because water forms a thin layer around sand grains, making them stick together and creating gaps. It affects concrete and mortar mix proportions, workability, material usage, and ultimately the strength and durability of structures. Builders must account for moisture content, use dry sand when possible, or measure sand by weight. Proper precautions ensure accurate mix design, cost efficiency, and safe construction.

Related IS Code Reference:

- IS 2386 (Part 3): Methods of Test for Aggregates for Concrete – Explains moisture content, bulking test, and corrections required.

- IS 456: Plain and Reinforced Concrete – Code of Practice – Mentions the importance of proper mix design considering bulking.

Read more Civil Engg topics

- Chlorination of water

- Per Capita Water Demand

- Advantages and Disadvantages of Sprinkler Irrigation

- Advantages and Disadvantages of Irrigation

- Drip Irrigation

- Viscosity

- Surface Tension

Conclusion

Bulking of sand is a very important concept in concrete and mortar mix design. It occurs when a thin film of moisture surrounds the sand particles, increasing their volume temporarily. If this effect is ignored, it can lead to incorrect mix proportions, poor workability, and reduced strength of concrete or mortar.

By understanding the bulking behavior and performing a simple bulking test on-site, engineers and site supervisors can make accurate adjustments in sand volume.

Using dry sand or measuring sand by weight instead of volume ensures precise batching and durable construction.

Thus, proper knowledge of the bulking of sand helps achieve better quality, strength, and economy in civil engineering works

FAQs on Bulking of Sand

1. What is the bulking of sand?

An increase in sand volume occurs when it contains moisture.

2. Why does bulking occur?

A thin water layer around sand grains creates voids and increases volume.

3. At what moisture content is bulking maximum?

4–6% moisture content.

4. Which type of sand bulks more?

Fine, angular, or unevenly graded sand.

5. How does bulking affect construction?

It can lead to incorrect mix proportions, reduced workability, material wastage, and weaker structures.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Bulking of Sand in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀