Introduction

In construction, seasoning of timber is essential to improve the quality and durability of wooden timber.

Although timber is one of the oldest and most reliable building materials. Freshly cut wood holds excess moisture, making it weak, heavy, and prone to fungal and insect attacks.

If this moisture is not removed before use, timber can warp, shrink, crack, or decay, leading to costly repairs and structural failures.

👉 Seasoning of timber is the controlled process of reducing the moisture content of wood to a suitable level for construction.

Proper seasoning makes timber stronger, more durable, and dimensionally stable, ensuring better performance in buildings, furniture, and other civil engineering works.

In this article, you will learn:

- The main objectives of seasoning

- Different types and methods of seasoning

- Advantages and common mistakes to avoid

- How proper seasoning helps boost timber strength and prevent losses

In simple terms, seasoning boosts the strength of timber and saves you from big losses caused by unseasoned wood.

Don’t forget to learn more about timber -including its properties, types, and uses in construction- in our detailed Ultimate Guide to Timber.

Objectives of Seasoning of Timber

Seasoning of timber is not just about drying the wood; it is a scientific process that prepares timber for long-term, safe, and economical use in construction.

Freshly cut timbers (also called green timber) usually contain more than 30–40% of moisture content.

If this moisture is not reduced to a safe level, the timber may warp, shrink, or decay, leading to structural failure and financial loss.

👉 Proper seasoning helps in achieving the following key objectives, which are listed below:

1. Reduce Excess Moisture Content

- The primary goal of seasoning is to reduce the timber’s moisture content to a safe range, usually 12–15% for construction use.

- High moisture makes the timber weak, heavy, and prone to shrinkage after installation.

- Controlled removal of water minimizes internal stresses, preventing cracks or surface checks.

👉 If a timber beam is used without seasoning, it may shrink over time and loosen the joints of a roof truss, causing instability.

2. Increase Strength and Load-Bearing Capacity

- Moisture-filled timber fibers are softer and weaker.

- When timber is properly seasoned, the fibers become compact and stronger.

- This increased strength allows the timber to carry higher loads, which is crucial for beams, columns, scaffolding, and other structural members.

👉 Seasoned timber is 20–50% stronger than unseasoned timber.

3. Improve Resistance Against Decay, Fungus, and Pests

- Wet timber creates a favorable environment for fungi, mold, and insects (like termites and borers).

- Seasoning of timber removes the moisture needed for its survival, making timber less vulnerable to biological attacks.

- This extends the lifespan of timber used in outdoor and indoor construction.

👉 Seasoned timber requires less frequent maintenance and replacement, saving time and money, so that the seasoning of timber is required

4. Ensure Dimensional Stability

- Green timber tends to expand, shrink, or warp with changes in humidity.

- Seasoning of timber stabilizes the timber by balancing the internal moisture with the surrounding environment.

- This helps maintain the timber’s original size and shape, ensuring precise fitting in doors, windows, furniture, and flooring.

👉 A poorly seasoned wooden door may swell during the rainy season and get stuck, while seasoned timber remains stable.

5. Enhance Workability and Surface Finish

- Seasoned timber is lighter and easier to saw, plane, drill, and shape compared to wet timber.

- It absorbs paint, polish, and adhesives more uniformly, resulting in a smoother and more attractive finish.

- This makes seasoned timber ideal for furniture, decorative panels, and exposed structural elements.

6. Reduce Long-Term Construction Costs

- Using unseasoned timber can lead to problems such as joint failures due to the shrinking of timber, cracks, and pest damage, which require expensive repairs.

- Properly seasoned timber minimizes these risks and thus saves money in the long run.

- Seasoning of timber also reduces wastage during cutting and shaping, improving efficiency in projects.

Types of Seasoning of Timber

Seasoning of timber means drying wood to reduce its moisture content to a safe level, usually around 12–15%, so it becomes strong, stable, and durable.

Proper seasoning prevents timber from shrinking, warping, cracking, or rotting during use.

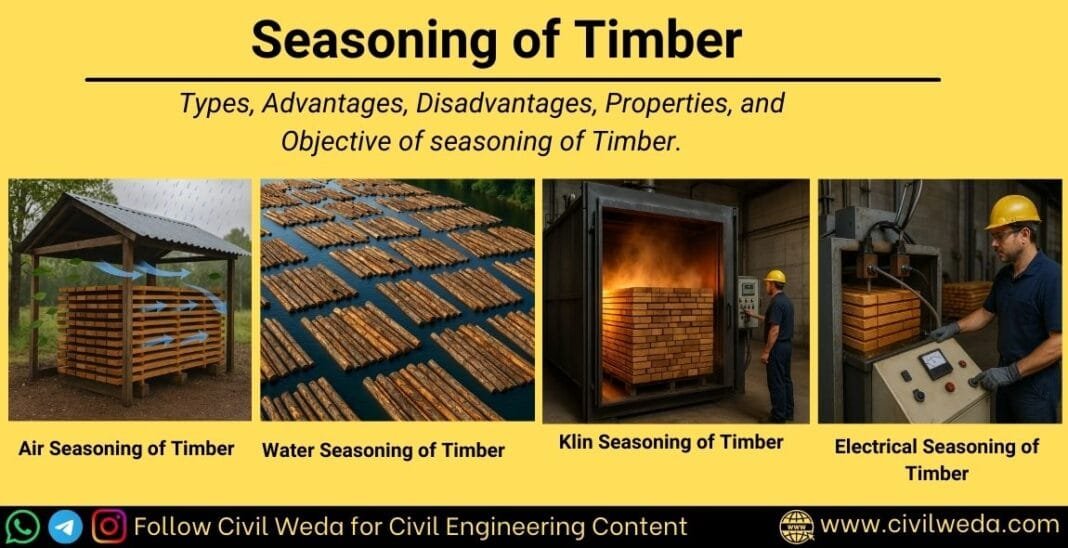

There are two main types of seasoning:

👉 Natural Seasoning – moisture of timber removed by using natural agents like air, water, or sunlight.

👉 Artificial Seasoning – moisture removed from timber controlled or removed by using heat, electricity, chemicals, or modern solar dryers.

1. Natural Seasoning of Timber

Natural seasoning uses nature’s processes, like air, water, and sunlight.

It is low-cost and eco-friendly, but slower than artificial methods.

The quality of drying depends on the local climate and the size of timber pieces.

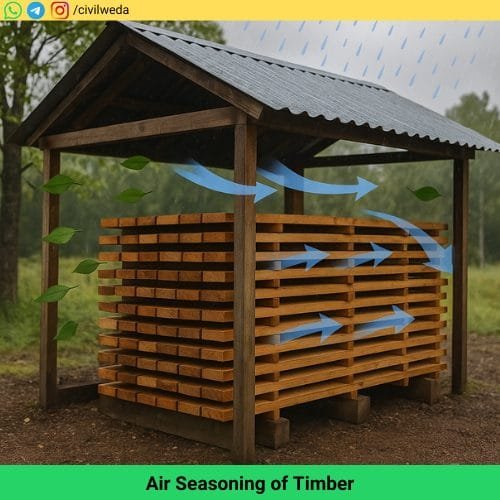

(a) Air Seasoning of timber

In this method of seasoning timber, Timber is cut into logs or planks and stacked in a well-ventilated shed to protect it from rain and direct sunlight. Small gaps (using thin wooden strips called stickers) are left between layers for air circulation. The air slowly removes moisture from the timber. Time required: 3–9 months (depends on the thickness and climate of the area).

Advantages of Air Seasoning of timber:

- Simple, eco-friendly, and inexpensive.

- Preserves most of the timber’s natural strength.

Disadvantages of Air Seasoning of timber:

- Very slow process.

- Drying depends on the weather; high humidity slows it down.

- Risk of surface cracks if drying is uneven.

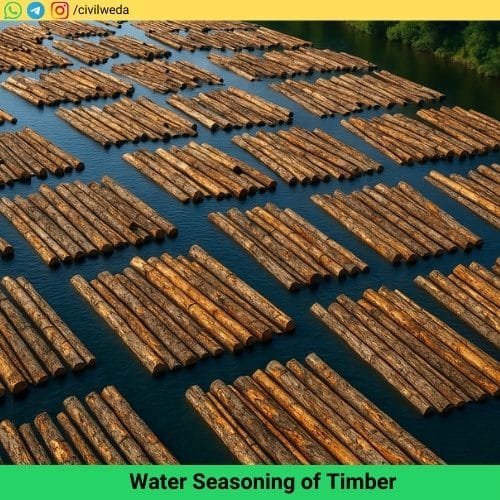

(b) Water Seasoning of timber

Timber logs are immersed in running water (like rivers or canals) for 2–4 weeks. The running water removes sap and soluble materials that attract insects and fungi. After immersion, timber is air-dried to remove the remaining moisture.

Advantages of Water Seasoning:

- Faster than air seasoning.

- Removes harmful sap, reducing the risk of decay and insect attack.

Disadvantages of Water Seasoning:

- Requires a continuous source of running water.

- May slightly reduce timber’s natural strength and elasticity.

- Not practical in regions without easy water access.

2. Artificial Seasoning of Timber

Artificial seasoning uses controlled techniques to remove moisture quickly and uniformly.

It is best for large-scale and commercial projects because it saves time and gives consistent quality.

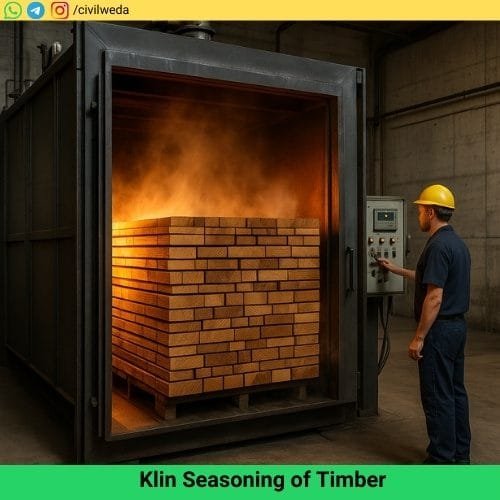

(a) Kiln Seasoning of Timber

Timber is placed inside a closed chamber called a kiln. Hot air with controlled temperature and humidity is circulated inside the kiln. The process is much faster than natural seasoning, usually taking a few days to 2–3 weeks. By controlling drying speed, cracking and warping can be minimized.

Advantages of Kiln Seasoning:

- Produces high-quality, uniformly seasoned timber.

- Quick and reliable compared to natural methods.

- Reduces fungal attack during drying.

Disadvantages of Kiln Seasoning:

- Requires expensive equipment and an energy supply.

- If drying is too fast or uneven, timber can crack.

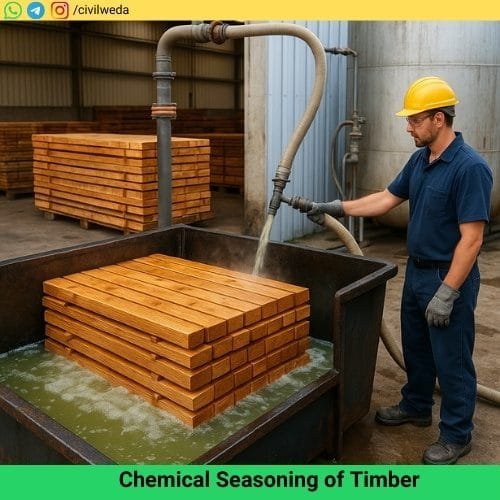

(b) Chemical Seasoning of Timber

Timber is soaked in a chemical solution (such as salts or preservatives). The solution replaces water from the timber. The timber is later air-dried or heated to remove remaining moisture.

Advantages of Chemical Seasoning:

- Faster than natural seasoning.

- Improves resistance to insects and decay.

Disadvantages of Chemical Seasoning:

- Higher cost due to chemicals.

- Requires skilled handling to prevent chemical damage.

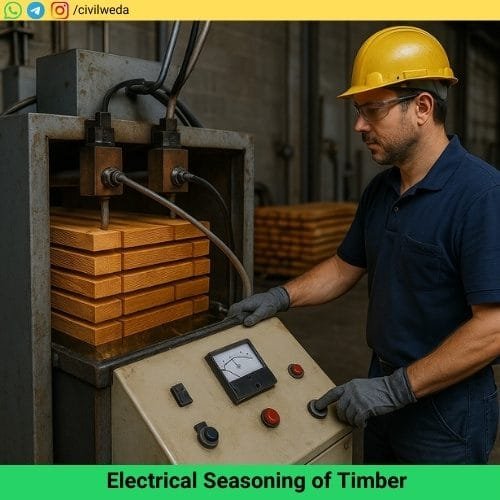

(c) Electrical Seasoning of Timber

- An electric current is passed through the timber.

- The resistance of wood to electricity generates heat, which evaporates moisture.

- This method is very fast and useful for smaller timber sections.

Advantages of Electrical Seasoning:

- Saves time — can season small pieces in hours or days.

- Reduces the risk of fungal attack during drying.

Disadvantages of Electrical Seasoning:

- Very expensive.

- Not suitable for large logs; mainly used in specialized industries.

(d) Solar Seasoning of Timber (Modern & Eco-Friendly method)

Uses solar dryers — transparent chambers that trap sunlight to produce heat while controlling airflow and humidity. Faster than open-air drying and cheaper than kiln seasoning.

Advantages:

- Environment-friendly and energy-efficient.

- Provides more uniform drying than traditional air seasoning.

Disadvantages:

- Relies on sunlight availability.

- Not as fast or consistent as kiln drying for large-scale production.

Comparison of Natural vs Artificial Seasoning of Timber

Proper seasoning improves timber quality, but the choice between natural and artificial methods depends on project needs like time, cost, and desired quality.

Here’s a detailed comparison:

Natural Seasoning of Timber

- Uses natural agents like air, water, and sunlight

- Takes more time (weeks to months)

- Low-cost, but depends on the climate

- Suitable for small-scale or traditional projects

Artificial Seasoning of Timber

- Uses controlled techniques like kiln, chemicals, or electricity

- Fast (days to weeks) and uniform drying

- Requires more investment and equipment

- Preferred for large-scale and commercial projects

| Feature | Natural Seasoning | Artificial Seasoning |

|---|---|---|

| Drying Agent | Air, sunlight, or water | Heat, electricity, chemicals |

| Time Required | Slow (weeks–months) | Fast (days–weeks) |

| Cost | Low | High |

| Quality of Timber | Variable, depends on weather | Uniform and high-quality |

| Strength & Durability | Moderate | Higher due to controlled drying |

| Fungal/Insect Attack | More prone | Less prone |

| Suitable For | Small projects, rural works | Commercial & industrial projects |

| Energy Requirement | None | High |

Advantages of Proper Seasoning of Timber

Proper seasoning of timber is the most crucial step in preparing wood for construction.

It not only improves the quality and performance of timber but also saves money by reducing future damage.

Here are the main advantages:

1. Increases Strength and Durability

- Seasoned timber is lighter and stronger because excess moisture is removed.

- It can safely bear heavy loads in beams, columns, and roof trusses.

- Properly seasoned timber lasts longer without deforming.

2. Protects Against Fungi and Insects

- Moisture is the main reason for fungal growth and insect attack (like termites).

- By lowering the moisture content to around 12–15%, seasoned timber becomes less attractive to pests.

- This protection reduces maintenance and replacement costs.

3. Improves Dimensional Stability

- Unseasoned timber shrinks, swells, or warps due to changes in humidity.

- Seasoned timber maintains a stable size and shape, making it ideal for doors, windows, and furniture.

- This stability ensures precise fitting and better finishing.

4. Enhances Workability

- Seasoned timber is easier to saw, drill, plane, and polish.

- Reduces wear and tear on tools.

- Offers a smooth surface for painting, polishing, and finishing.

5. Reduces Structural Problems

- Unseasoned timber often causes joint loosening, cracks, and uneven surfaces after installation.

- Proper seasoning minimizes these risks, ensuring stronger and safer structures.

6. Cost-Effective in the Long Run

- Seasoned timber reduces losses due to damage, repair, and pest infestation.

- Lower wastage during construction leads to better use of resources.

- Though artificial seasoning may seem expensive initially, it saves significant money over time.

7. Environment-Friendly Use of Timber

- Long-lasting, well-seasoned timber means less frequent harvesting of new trees.

- This helps in sustainable construction practices.

Disadvantages / Limitations of Improper Seasoning of Timber

Seasoning is not just about drying timber; it determines how strong and long-lasting the wood will be in construction.

When timber is not seasoned properly or used while it is still “green,” it can cause serious structural, financial, and maintenance problems.

Here’s a detailed discussion on Improper Seasoning of Timber:

1. Reduced Strength and Load-Bearing Capacity

Due to improper seasoning of timber, its strength and load-bearing capacity are reduced. Because of-

- Wet timber contains excess water that weakens the wood fibers.

- Such timber cannot bear heavy loads effectively and may bend or break under pressure.

- Structural elements like beams, rafters, and trusses lose their designed strength.

Example:

A poorly seasoned roof timber-beam can sag or crack within a few years, increasing the risk of the roof and it collapse at any time.

2. Shrinkage, Warping, and Cracking

- Timber naturally shrinks as it loses moisture.

- If it is used before proper seasoning, the moisture continues to evaporate after installation.

- This uneven drying causes warping (bending, twisting, or bowing of timber) and sometimes surface or internal cracks.

- Wooden doors or windows may swell during the monsoon and shrink in the summer, leading to jamming or gaps.

- Flooring made of unseasoned timber can develop uneven surfaces or split over time.

3. Higher Risk of Fungal Decay and Insect Attack

- Fungi, mold, and termites thrive in moist timber.

- Unseasoned timber becomes a breeding ground for pests, leading to decay, weakening, and early failure.

- Pest damage often spreads to nearby wooden elements in the building.

Financial Impact:

Repairing or replacing damaged timber due to termites or rot can cost as much as or more than the initial material.

4. Structural Instability and Poor Performance

- Green timber continues to shrink after installation, loosening nails, screws, and joints.

- Distorted wooden members can compromise the alignment of the entire structure, such as doors not closing properly or beams shifting out of place.

- In scaffolding or formwork, using unseasoned timber can be unsafe and lead to construction accidents.

5. Increased Maintenance and Long-Term Costs

- Unseasoned timber requires frequent pest control treatments and protective coatings.

- Warped or cracked components must be replaced sooner, increasing the total project cost.

- Contractors and builders often face delays and financial losses due to frequent repairs.

In simple words, we can say that improper seasoning of timber reduces the strength, stability, and durability of timber, making it an unreliable material for construction. While it may seem cheaper at the beginning to skip proper seasoning, it often results in much higher expenses and serious structural issues later. This is why proper seasoning should always be considered an essential step in preparing timber for safe and long-lasting use.

Applications of Seasoned Timber in Civil Engineering

Seasoned timber is a vital material in civil engineering because it offers strength, stability, and durability.

Its controlled moisture content makes it more reliable and efficient for a wide range of construction and finishing purposes.

Properly seasoned timber not only performs better but also reduces future maintenance and replacement costs.

1. Scaffolding and Temporary Structures

One of the most common uses of seasoned timber in civil engineering is in scaffolding and other temporary construction structures.

Because of its reduced moisture content, seasoned timber is stronger and lighter, which makes it safer for workers and easier to handle on-site. It does not warp or bend under load, ensuring stable and secure temporary platforms during construction and maintenance works.

2. Formwork and Shuttering

Seasoned timber is widely used in formwork or shuttering, which holds concrete in place while it sets.

Its stable dimensions prevent warping or shrinking when exposed to wet concrete, ensuring that the required shape and size of structural elements are maintained.

The smooth surface of seasoned timber also makes it easy to remove after the concrete has hardened, leaving behind clean and accurate finishes.

3. Doors, Windows, and Frames

Doors, window frames, and interior fittings made from seasoned timber are less likely to shrink, swell, or jam due to changes in humidity.

This dimensional stability ensures long-lasting performance and reduces the need for frequent repairs.

Seasoned timber also allows for precise joinery, giving a smooth, polished look to interior and exterior fittings.

4. Furniture and Interior Woodwork

For furniture, seasoned timber is the preferred choice because it is easier to shape, carve, and polish.

Its reduced moisture content helps prevent cracking, twisting, or swelling, even in changing weather conditions.

This makes it ideal for long-lasting furniture, cabinets, flooring, and decorative wooden panels in homes and commercial spaces.

5. Roof Trusses and Beams

Seasoned timber is often used for making roof trusses, rafters, and beams because of its enhanced strength and durability.

Unlike unseasoned wood, it does not deform under the weight of the roof or due to seasonal moisture changes.

Its stability helps maintain the structural integrity of roofs and other load-bearing wooden components.

6. Bridges, Poles, and Heavy Construction Works

In some regions, seasoned timber is used in small bridges, poles, piles, and similar heavy construction elements.

Its ability to resist decay and maintain its shape under load makes it suitable for outdoor applications where both strength and durability are critical.

Although concrete and steel are now more common for large structures, seasoned timber still serves well in rural and temporary projects.

Read more Civil Engg topics

- Chlorination of water

- Per Capita Water Demand

- Pile foundation

- Drip Irrigation

- Viscosity

- Surface Tension

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

Conclusion

Seasoning of timber is one of the most important steps in preparing wood for construction.

Reducing the moisture content to a safe level makes timber stronger, more stable, and less prone to fungal decay or insect attack.

Structures built with properly seasoned timber last longer, perform better, and require far less maintenance.

On the other hand, using unseasoned or improperly seasoned timber can result in serious problems such as shrinkage, warping, joint failures, and pest infestation.

These issues not only increase construction and repair costs but also compromise safety and durability.

In modern civil engineering, kiln seasoning and other artificial methods have become more common because they save time and provide uniform quality.

However, natural methods like air and water seasoning still serve well in small-scale or traditional projects.

FAQs on Seasoning of Timber

1. What is the ideal moisture content of timber after seasoning?

The ideal moisture content for construction timber is usually 12–15%, which keeps it stable and strong under normal weather conditions.

2. Which seasoning method of timber is the fastest and most reliable?

Kiln seasoning is the fastest and most reliable method because it uses controlled heat and humidity to dry timber evenly in just a few days or weeks.

3. Why is it risky to use unseasoned timber in construction?

Unseasoned timber can shrink, warp, and crack after installation.

It is also more prone to decay and insect attack, which weakens the structure and increases long-term costs. So it is risky to use it in construction.

4. Which method is best for small-scale or traditional projects?

For small-scale or rural projects, air seasoning of timber is often preferred because it is simple and low-cost, though it takes more time than artificial methods.

5. How does proper seasoning reduce construction costs?

Properly seasoned timber lasts longer, requires fewer repairs, and reduces damage from pests or warping.

This saves both time and money throughout the life of the structure.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Seasoning of Timber, along with its objective, types, and applications in civil engineering. If you found this complete guide useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀