Introduction

Rapid Hardening Cement (RHC) is a special type of cement that gains strength much faster than Ordinary Portland Cement (OPC). It is mainly used in construction projects where early strength, speedy progress, and quick removal of formwork are essential. Due to its fine grinding and higher percentage of tricalcium silicate (C3S), this cement sets and hardens more rapidly. In this article, we will discuss the properties, advantages, disadvantages, and uses of Rapid Hardening Cement in detail.

What is Rapid Hardening Cement:

Rapid Hardening Cement (RHC), also known as High Early Strength Cement, is a special type of cement designed to achieve strength much faster than Ordinary Portland Cement (OPC). It is manufactured by finely grinding clinker with a comparatively higher percentage of tricalcium silicate (C₃S), usually around 56–60%. This finer grinding increases the rate of hydration, which results in quicker setting and higher early strength. As per IS 8041:1990, RHC must satisfy specific chemical and physical requirements to ensure quality and durability. Remarkably, the compressive strength of Rapid Hardening Cement at just 3 days is almost equal to the 7-day strength of Ordinary Portland Cement.

Rapid Hardening Cement (RHC) is suitable for use in both Plain Cement Concrete (PCC) and Reinforced Cement Concrete (RCC). Its ability to gain high early strength makes it particularly useful for road works, precast members, and urgent repair projects.

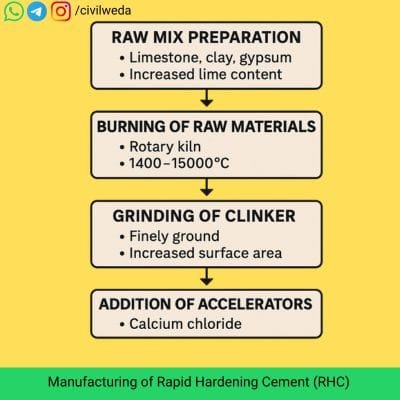

Manufacturing of Rapid Hardening Cement (RHC)

The manufacturing of Rapid Hardening Cement is broadly similar to Ordinary Portland Cement (OPC), but certain changes in the raw mix and the grinding process make it achieve high early strength.

1. Selection of Raw Materials

- Limestone – primary source of lime

- Clay or shale – provides silica and alumina

- Gypsum – regulates the setting time

2. Clinker Formation

- The raw materials are proportioned and burned in a rotary kiln at 1400–1500°C.

- For RHC, the mix contains more lime and relatively less silica and alumina compared to OPC.

- This adjustment increases the proportion of tricalcium silicate (C₃S ~ 56–60%), which is mainly responsible for early strength development.

3. Finer Grinding of Clinker

- The cooled clinker is ground much finer than in the case of OPC.

- The finer particles offer a larger surface area for hydration, which accelerates the setting and strength gain.

4. Use of Additives (Optional)

- In some cases, a small percentage of calcium chloride may be added as an accelerator.

- This further enhances the early hydration and quick strength gain of the cement.

5. Final Storage and Packing

- The finished cement is stored in airtight silos to avoid moisture contact.

- After quality checks, it is packed and supplied for use in construction works.

Property of Rapid Hardening Cement

The main properties of Rapid Hardening Cement, as per IS 8041:1990, are as follows:

- Initial Setting Time: Should not be less than 30 minutes, which allows sufficient time for placing and compacting the mix.

- Final Setting Time: Should not exceed 600 minutes (10 hours), ensuring that the cement hardens within a reasonable period.

- Fineness (Specific Surface): Must be at least 3250 cm²/g, indicating that the cement is ground much finer than OPC.

- Soundness (Le Chatelier Test): Expansion should be within 10 mm, which confirms dimensional stability after setting.

- Compressive Strength:

- At 1 day → equal to 3-day strength of OPC

- At 3 days → almost equal to the 7-day strength of OPC

(when tested with the same water–cement ratio)

These unique properties make Rapid Hardening Cement ideal for time-bound projects, where early load-bearing capacity and faster progress are essential.

Advantages of Rapid Hardening Cement (RHC)

The major advantages of using Rapid Hardening Cement are listed below, which explain why it is preferred in time-bound and special construction works.

- Early Strength Development:

RHC gains strength much faster than OPC, which allows formwork and shuttering to be removed earlier, thereby speeding up the construction cycle. - Time-Saving:

Highly beneficial for urgent projects, emergency repair works, and structures with strict deadlines, as it helps achieve rapid progress. - Better Durability:

Compared to OPC, RHC provides greater resistance against sulphate attack, which improves the long-term durability of concrete structures. - Cold Weather Concreting:

Its faster setting and hardening properties make it useful in frost-prone areas, reducing the risk of damage due to freezing conditions. - Reduced Curing Period:

Requires less curing time, saving both water and labor costs, making it more economical in the long run despite its higher price.

Disadvantages of Rapid Hardening Cement (RHC)

Along with several benefits, Rapid Hardening Cement also has some limitations that should be kept in mind before using it in construction:

- Higher Cost:

RHC is generally 10–15% more expensive than Ordinary Portland Cement (OPC), which increases the overall project cost, especially in large-scale works. - High Heat of Hydration:

This cement releases more heat during hydration, making it unsuitable for mass concreting such as dams or thick foundation blocks, as it may lead to shrinkage cracks. - Risk of Shrinkage:

If proper curing is not carried out, there is a possibility of plastic or drying shrinkage, which can reduce the durability of the structure. - Limited Availability:

In some regions, RHC is not produced in large quantities, making it difficult to procure compared to OPC. - Not Suitable for All Structures:

Rapid Hardening Cement is usually avoided in continuous water-exposed structures such as dams, underwater works, or large reservoirs, where slower hydration is preferred.

Applications of Rapid Hardening Cement (RHC)

Rapid Hardening Cement is widely used in construction projects where early strength and speedy progress are required. Some of its important applications are listed below:

- Road Pavements and Highways:

Ideal for road and pavement works where traffic needs to be allowed quickly, reducing delays and improving efficiency. - Precast Concrete Products:

Commonly used in the production of poles, slabs, blocks, railway sleepers, and precast panels, as it allows quick demoulding and rapid production cycles. - Cold Weather Concreting:

Its fast hydration and early strength help in preventing frost damage, making it suitable for concreting in colder regions. - Repair and Rehabilitation Works:

Useful for bridge decks, airport runways, industrial floors, and structural repairs, where downtime must be minimized. - Urgent or Emergency Constructions:

Applied in temporary structures, disaster rehabilitation, and emergency repair works, where speed is the most critical factor.

Comparison: Rapid Hardening Cement (RHC) vs Ordinary Portland Cement (OPC)

This comparison clearly shows that while Rapid Hardening Cement is ideal for projects requiring early strength and speed, Ordinary Portland Cement remains the most economical choice for general construction.

| Property | Rapid Hardening Cement (RHC) | Ordinary Portland Cement (OPC) |

|---|---|---|

| Early Strength | Gains very high strength in the first 3 days (≈ OPC 7-day strength) | Moderate, requires more time to develop full strength |

| Setting Time | Faster setting, useful in urgent works | Normal setting time, suitable for most works |

| Cost | About 10–15% more expensive than OPC | Cheaper and more economical |

| Curing Requirement | Requires less curing time, saving water & labor | Needs longer curing for desired strength |

| Applications | Roads, highways, precast elements, repair & emergency works | Needs longer curing for the desired strength |

Read our other Post

Conclusion

Rapid Hardening Cement is a highly effective material for projects that demand early strength and speedy construction. Its quick setting, durability, and suitability for time-bound works make it ideal for roads, precast elements, cold-weather concreting, and urgent repair projects.

However, due to its higher cost, shrinkage risk, and high heat of hydration, it must be used selectively and not in mass concreting or continuous water-exposed structures. When applied in the right situations, RHC helps save time, reduce project delays, and optimize resources, making it a valuable choice in modern construction.

Thank you for reading this article on Rapid Hardening Cement. We hope this information helped you understand its properties, advantages, disadvantages, and uses. If you found this post useful, do share it with your friends and fellow civil engineering learners. For more construction-related content, stay connected with Civil Weda.

FAQs on Rapid Hardening Cement

1. What is the main advantage of Rapid Hardening Cement?

The biggest advantage of RHC is its early strength development, which allows quick removal of formwork and faster progress in construction.

2. Is Rapid Hardening Cement the same as Quick Setting Cement?

No. Although both are fast in action, Quick Setting Cement sets rapidly but does not gain early strength, while RHC develops strength much faster than OPC.

3. Can Rapid Hardening Cement be used in mass concrete works?

It is generally not recommended for mass concreting (like dams or thick sections) because its high heat of hydration may lead to cracking.

4. What are the common uses of Rapid Hardening Cement?

RHC is commonly used in road pavements, precast products, repair works, and emergency construction projects where time is a critical factor.

5. Why is Rapid Hardening Cement more expensive than OPC?

It is costlier because of finer grinding, higher lime content, and better quality control during manufacturing, which increases

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Rapid Hardening Cement in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀