Introduction

Bitumen concrete is a very common material used in road construction. It is popular because of its strength, durability, and smooth surface. Highways, city roads, parking areas, and even airport runways are mostly built with bitumen concrete. It is preferred by engineers since it is cheaper than cement concrete, quick to construct, and easy to repair.

For civil engineering students, bitumen concrete is also an important exam topic in SSC JE, GATE, State AE/JE, and university exams.

However, this material has both advantages and disadvantages; it provides useful advantages like cost-effectiveness and smooth roads, while on the other hand, it has hidden drawbacks such as low resistance to high temperatures and shorter life compared to cement concrete.

In this article, we will learn:

- The definition and ingredients of bitumen concrete

- Its types and properties

- Its advantages and disadvantages

- Applications in construction

- And the difference between bitumen concrete and cement concrete

For a complete overview of bitumen, check our detailed guide on What is Bitumen? Types, Properties, Advantages, Disadvantages

This guide will help you in exams as well as in understanding its practical use in construction.

What is Bitumen Concrete?

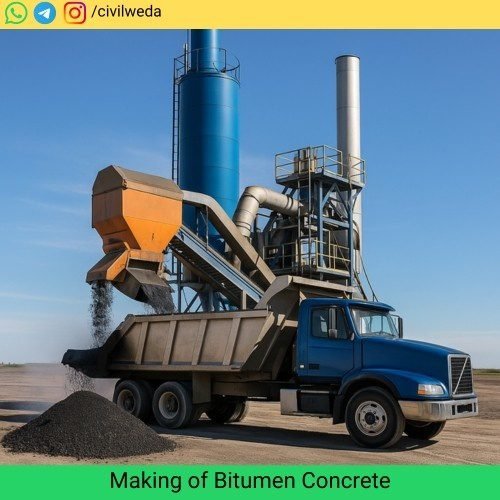

Bitumen concrete is a specially designed mixture of bitumen and graded aggregates used in road construction. It is also known as bituminous concrete. This material is mainly used for making the top layer of flexible pavements because it provides a strong, smooth, and durable surface. As per the Indian Road Congress IRC Bituminous Concrete is the mixture of coarse aggregates, fine aggregates, filler material, and bitumen binder, prepared in a hot mix plant and laid on the road surface to form a dense, durable, and impermeable pavement layer of the Road.

It is a mixture of:

- Bitumen acts as a binder, which holds all the particles together.

- Aggregates (coarse, fine, and filler) give the required strength and stability to the mix.

When the right proportion of bitumen and aggregates is mixed and laid properly, it forms a dense, flexible, and weather-resistant road surface. This makes it highly suitable for highways, expressways, city roads, and airport runways where heavy traffic load is expected.

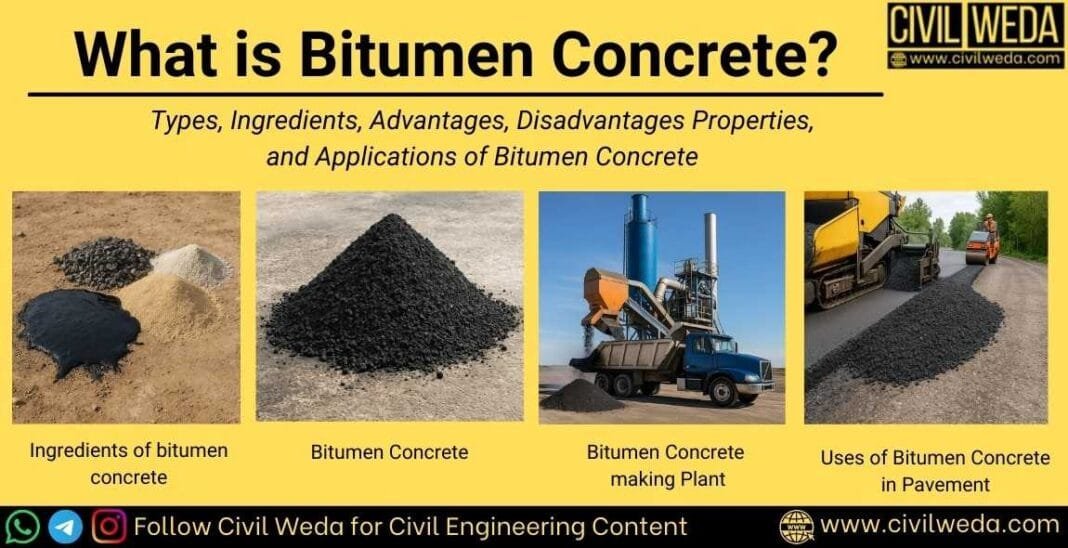

Ingredients of Bitumen Concrete

Bitumen concrete is made by mixing different materials in a proper proportion. Each ingredient plays an important role in giving the pavement strength, durability, and flexibility.

1. Coarse Aggregates

- These are crushed stones of larger size, generally 10 mm to 20 mm.

- Their main role is to provide strength, stiffness, and load-bearing capacity.

- Angular and rough-textured aggregates are preferred, as they give better interlocking and resistance against traffic loads.

2. Fine Aggregates

- These are smaller particles like natural sand or crushed stone dust.

- They fill the voids between coarse aggregates and ensure better compaction and stability.

- Fine aggregates also improve the workability and finish of the road surface.

3. Filler Material

- Filler consists of very fine particles such as cement, hydrated lime, fly ash, or mineral dust.

- It improves the binding property of bitumen and fills up micro-voids.

- The use of lime as a filler also helps in reducing the stripping (loss of bond between bitumen and aggregates).

4. Bitumen Binder

- Bitumen is the most important component of this mix.

- It works as a binding agent that holds all aggregates together.

- It provides flexibility, waterproofing, and resistance against weathering and traffic loads.

- Different grades of bitumen are used depending on the climate and traffic conditions (for example, VG-30, VG-40).

5. Additives or Modifiers

- In some cases, additives like polymers, anti-stripping agents, or crumb rubber are added.

- These improve the durability, temperature resistance, and overall performance of the pavement.

- Polymer Modified Bitumen (PMB) and Crumb Rubber Modified Bitumen (CRMB) are common examples.

In short, we can say that Bitumen concrete is a carefully designed mixture of coarse aggregates, fine aggregates, filler material, and bitumen binder, sometimes improved with additives to increase its service life and strength.

Types of Bitumen Concrete

The performance of a bituminous pavement depends on the type of bitumen concrete used. Different types are selected based on traffic intensity, climatic conditions, and pavement design requirements. The Indian Roads Congress (IRC) and MoRTH specifications classify them as follows:

1. Dense Bituminous Concrete (DBC)

- This is the most widely used type in highways and expressways.

- Made with dense-graded aggregates, which means there are very few air voids.

- Provides high strength, durability, impermeability, and smooth surface finish.

- It is generally used as the wearing course (top surface layer) in flexible pavements.

2. Semi-Dense Bituminous Concrete (SDBC)

- Contains more voids compared to DBC, hence less dense.

- Suitable for moderate traffic roads where cost-saving is important.

- Offers a balance between economy and performance, though less durable than DBC.

3. Bituminous Macadam (BM)

- An open-graded mix with relatively large aggregates.

- Provides structural strength but is permeable to water, so it must be covered with a surface layer.

- Commonly used as a base course below the wearing surface.

4. Open-Graded Premix Carpet (OGPC)

- Consists of a single-sized aggregate mix with high air voids.

- Provides a rough surface texture with good skid resistance.

- Used as a thin surface layer on low and medium-traffic roads.

- Needs a seal coat to improve its life and waterproofing.

5. Modified Bituminous Concrete

- Uses Polymer Modified Bitumen (PMB) or Crumb Rubber Modified Bitumen (CRMB) instead of ordinary bitumen.

- Designed to withstand extreme temperatures and heavy traffic loads.

- Commonly used in airports, intersections, and high-volume roads where normal mixes may fail.

| Type | Key Features | Typical Use |

|---|---|---|

| Dense Bituminous Concrete (DBC) | Dense-graded mix, very few voids, strong and durable | Highways, expressways, wearing course (top layer) |

| Semi-Dense Bituminous Concrete (SDBC) | Less dense than DBC, economical, moderate durability | Moderate traffic roads |

| Bituminous Macadam (BM) | Open-graded, large aggregates, needs surface cover | Base course for pavements |

| Open-Graded Premix Carpet (OGPC) | High air voids, rough texture, good skid resistance | Low and medium traffic roads, thin surface layer |

| Modified Bituminous Concrete (PMB/CRMB) | Uses polymers or rubber, withstands heavy loads and temperature variations | Airports, intersections, high-volume traffic roads |

Properties of Bitumen Concrete

The performance of bitumen concrete depends on its physical and mechanical properties. These properties ensure that the pavement can handle heavy traffic, resist weather conditions, and provide a safe driving surface.

1. High Strength

- Bitumen concrete can carry heavy wheel loads without breaking.

- Properly compacted aggregates provide good interlocking and structural strength.

- This makes it suitable for highways, expressways, and airport runways.

2. Durability

- It performs well for many years under traffic and weather conditions.

- Proper mix design and periodic maintenance increase its service life.

- Compared to ordinary surface treatments, bitumen concrete lasts much longer.

3. Impermeability

- A dense mix does not allow water to seep into lower layers.

- This property prevents pavement failure due to moisture and increases durability.

4. Flexibility

- Unlike rigid pavements, bitumen concrete is flexible in nature.

- It can expand in hot weather and contract in cold weather without major cracks.

- This makes it more suitable for areas with temperature variations.

5. Workability

- Easy to produce, transport, and lay using hot mix plants and pavers.

- Good workability ensures uniform thickness, proper compaction, and smooth surface finish.

6. Skid Resistance

- Provides a safe and non-slippery surface for vehicles.

- The rough texture of aggregates increases friction, especially during rainy conditions.

7. Temperature Sensitivity

- One limitation is that it becomes soft at high temperatures (rutting and bleeding may occur).

- At very low temperatures, it becomes brittle and prone to cracking.

- To overcome this, modified bitumen (PMB or CRMB) is often used.

Advantages of Bitumen Concrete

Bitumen concrete has become the first choice for road construction across the world. Its popularity is due to several practical, technical, and economic benefits.

1. Cost-Effective

- The construction cost is much lower than cement concrete pavements.

- Both initial cost and life-cycle cost (maintenance + repair) are economical.

- For developing countries like India, this is a major advantage.

2. Quick and Easy Construction

- Bituminous roads can be constructed and opened to traffic within 24–48 hours, unlike cement concrete roads that require curing time.

- Useful for emergency road works and projects where speed is important.

3. Smooth and Comfortable Riding Surface

- Provides a uniform, skid-resistant surface that ensures safe driving.

- Reduces vehicle operating cost by lowering fuel consumption and tyre wear.

- Improves travel comfort on highways and urban roads.

4. Easy Maintenance and Repair

- Damaged sections (like potholes, cracks, or ruts) can be repaired locally without disturbing the entire pavement.

- Repair work requires less time, less labor, and less cost.

- Maintenance can be done even in traffic zones with minimum disruption.

5. Flexibility and Resilience

- Bitumen concrete can expand in hot weather and contract in cold weather without cracking.

- It can absorb minor settlements of the subgrade, which rigid cement concrete cannot.

- This makes it suitable for a wide range of climatic conditions.

6. Better Noise Control

- Bituminous roads produce less traffic noise compared to rigid pavements.

- This makes them more suitable for urban and residential areas.

7. Recyclability and Sustainability

- Old bituminous pavement materials can be reclaimed and reused in new construction.

- Use of Reclaimed Asphalt Pavement (RAP) reduces environmental impact.

- This makes it a sustainable and eco-friendly option in modern road construction.

8. Good Performance Under Traffic

- Provides excellent skid resistance due to rough aggregates.

- It can handle heavy traffic loads effectively if designed and maintained properly.

In short, Bitumen concrete is economical, quick to build, smooth for driving, flexible, easy to repair, and sustainable. These advantages make it the most preferred material for highways, city roads, and airports.

Disadvantages (Hidden Drawbacks) of Bitumen Concrete

While bitumen concrete is widely used in road construction, it is not free from limitations. Understanding these drawbacks is important for proper design, maintenance, and long-term performance.

1. Temperature Sensitivity

- Bitumen is highly sensitive to temperature changes.

- In hot climates, the surface may soften, causing rutting, bleeding, and surface deformation under traffic loads.

- In cold climates, it becomes brittle and may crack easily.

- This limits its performance in extreme weather regions.

2. Shorter Service Life Compared to Cement Concrete

- A well-constructed bituminous road usually lasts 8–12 years with regular maintenance.

- In comparison, cement concrete pavements can last 20–30 years with less maintenance.

- Hence, bitumen roads require frequent renewal.

3. Susceptibility to Water Damage

- If water enters through surface cracks or poorly compacted joints, it can weaken the bond between bitumen and aggregates (stripping effect).

- Continuous water exposure may lead to potholes, raveling, and early pavement failure.

4. High Maintenance Requirement

- Though repairs are easy and inexpensive, bituminous roads need frequent maintenance to remain serviceable.

- Over time, these repeated maintenance costs can become higher than expected.

5. Environmental Concerns

- Bitumen is a by-product of petroleum refining. Its production and heating during mixing release greenhouse gases.

- Old bituminous layers, when removed and disposed of improperly, can add to pollution.

- Although recycling is possible, it is not always practiced.

6. Limited Resistance to Heavy Loads

- Continuous heavy or overloaded vehicles can cause permanent deformation, rutting, and fatigue cracking.

- For such situations, special modified bitumen mixes (PMB, CRMB) are required, which increase the cost.

7. Aesthetic Limitations

- The surface of bitumen concrete is usually dull and black.

- It lacks the aesthetic appeal of cement concrete pavements, especially in modern urban roads where appearance also matters.

In short, we can say that Bitumen concrete is flexible and economical, but it has hidden drawbacks like temperature sensitivity, shorter lifespan, water damage, and frequent maintenance needs. These factors must be considered before selecting it for road projects.

Applications of Bitumen Concrete

Bitumen concrete is one of the most widely used materials for flexible pavements. Its versatility makes it suitable for a variety of construction works, ranging from small village roads to large expressways and airports.

1. Highways and Expressways

- Used as the wearing course (top surface layer) in national and state highways.

- Provides a smooth, durable, and skid-resistant surface suitable for high-speed traffic.

2. Urban and City Roads

- Commonly used in municipal and residential streets.

- Offers low noise, smooth ride quality, and quick maintenance, which is important in busy cities.

3. Airport Runways and Taxiways

- Bituminous concrete is used in runways, taxiways, and aprons due to its ability to handle heavy wheel loads.

- Provides a smooth surface that reduces impact on aircraft tires.

4. Parking Areas

- Used in public and private parking lots because it is cost-effective and easy to repair.

- It can be resurfaced quickly without long closures.

5. Industrial and Commercial Areas

- Suitable for warehouses, container yards, and industrial roads where heavy vehicle movement is common.

- Modified bitumen mixes are often used in these areas for better durability.

6. Rural and Village Roads

- Bituminous concrete is also used in low to medium-traffic rural roads as an economical option.

- Provides all-weather connectivity in rural regions.

Difference Between Bitumen Concrete and Cement Concrete

Bitumen concrete and cement concrete are the two most commonly used materials in road construction. Both have their own strengths and limitations. The following table shows their main differences:

| Aspect | Bitumen Concrete (Flexible Pavement) | Cement Concrete (Rigid Pavement) |

|---|---|---|

| Material | Mix of bitumen + aggregates | Mix of cement + sand + aggregates + water |

| Flexibility | Flexible, can expand/contract with temperature and traffic | Rigid, cannot adjust to minor settlement |

| Strength | Moderate strength, suitable for medium to heavy traffic | Very high strength, suitable for heavy and overloaded traffic |

| Lifespan | 8–12 years (with regular maintenance) | 20–30 years (with little maintenance) |

| Cost | Lower initial cost, economical for construction | Higher initial cost, but economical in long term |

| Construction Time | Higher initial cost, but economical in the long term | Slow, requires curing (14–28 days) before use |

| Maintenance | Quickly, roads can be opened within 24–48 hours | Difficult and costly, but less frequent |

| Noise Level | Produces less traffic noise | Easy and low-cost, but frequent maintenance is needed |

| Recyclability | Can be recycled and reused (RAP material) | Limited recycling, mostly broken into aggregates |

| Aesthetic Appeal | Dull black appearance | Smooth and brighter surface |

| Best Use | Highways, expressways, city roads, airports, rural roads | Produces more noise due to the rigid surface |

Read more Civil Engg topics

- Chlorination of water

- Difference between bitumen and tar

- Pile foundation

- Drip Irrigation

- Viscosity

- Surface Tension

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Cement

Conclusion

Bitumen concrete is one of the most widely used materials in road construction because of its low cost, fast construction, flexibility, and smooth surface. It is the preferred choice for highways, city roads, airports, and parking areas.

At the same time, it also has some hidden drawbacks like shorter lifespan, temperature sensitivity, and high maintenance needs. Therefore, engineers must design it carefully and use modified bitumen mixes when required for heavy traffic or extreme weather.

👉 In short: Bitumen concrete is economical and practical for most road projects, but cement concrete may be preferred where long life and low maintenance are more important.

FAQs on Bitumen Concrete

Q1. What is bitumen concrete?

Bitumen concrete is a mix of bitumen and aggregates used for flexible pavements in roads, highways, and airports.

Q2. What are the main ingredients of bitumen concrete?

Coarse aggregates, fine aggregates, filler material, and bitumen binder.

Q3. Where is bitumen concrete used?

It is mainly used in highways, city roads, airport runways, parking areas, and rural roads.

Q4. What are the advantages of bitumen concrete?

It is economical, quick to construct, easy to repair, smooth for riding, and recyclable.

Q5. What are the disadvantages of bitumen concrete?

It has a shorter lifespan, is sensitive to temperature, and needs frequent maintenance.

Thank you 🙏 for spending your valuable time reading this article. We hope this guide helped you understand Bitumen Concrete simply and clearly. Keep learning, keep growing, and stay connected with Civil Weda for more exam-oriented and practical civil engineering content. 🚀