Introduction

Water is one of the most damaging elements for any structure. If leakage or dampness enters walls, roofs, or basements, it weakens concrete, corrodes steel, and reduces the life of the building. That’s why waterproofing is not just an option but a necessity in construction.

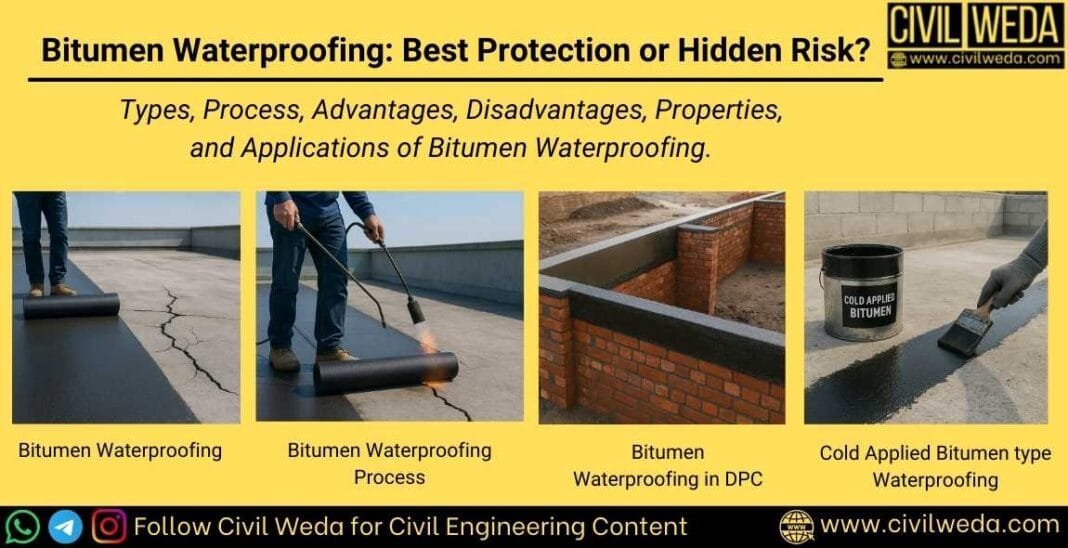

Among many techniques, bitumen waterproofing is one of the most trusted and widely used solutions. Bitumen, a thick and sticky material, forms a strong protective barrier that prevents water from seeping inside the structures. From roofs and basements to bridges and water tanks, it is applied in many critical areas of construction.

But here comes the main concern — Is bitumen waterproofing really the best protection for your structure, or does it carry hidden risks you should know about? In this article, we will cover everything: its meaning, types, process, advantages, disadvantages, applications, and cost, so you can decide whether it’s the right choice for your project.

What is Bitumen Waterproofing?

Bitumen waterproofing is a technique used to protect buildings and structures from water damage by applying a layer of bitumen-based material. Bitumen is a black, sticky, and highly viscous substance derived from crude oil. Because of its strong adhesive and waterproofing properties, it has been widely used in construction for decades.

In simple words, bitumen waterproofing acts like a protective shield. It prevents water from penetrating concrete, brickwork, or metal, and stops problems such as leakage, dampness, and corrosion of steel reinforcement. This not only increases the life of the structure but also reduces long-term repair costs.

Where is it commonly used?

- Flat and sloped roofs

- Basements and foundations

- Damp Proof Course (DPC) to stop rising damp in walls

- Bridges and tunnels

- Water tanks and reservoirs

Thanks to its flexibility, durability, and cost-effectiveness, bitumen waterproofing continues to be one of the most preferred solutions in the construction industry.

Types of Bitumen Waterproofing

Bitumen waterproofing can be applied in different forms depending on the requirements of the structure. Each type has its own process, benefits, and limitations. The most common types are:

1. Hot Applied Bitumen

- In this method, bitumen is heated at high temperature until it becomes liquid.

- The hot liquid is then applied directly to the surface with brushes or mops.

- It forms a continuous, seamless, and highly durable waterproofing layer.

👉 Commonly used in bridges, basements, and heavy-duty waterproofing works.

2. Cold Applied Bitumen (Bitumen Emulsion)

- Here, bitumen is mixed with water and emulsifiers to form an emulsion.

- It can be applied without heating, making the process safer and easier.

- After application, water evaporates and leaves behind a waterproof film.

👉 Mostly used in residential construction and small-scale works.

3. Self-Adhesive Bitumen Membranes

- These are factory-prepared sheets with a protective backing.

- They can be directly stuck onto the surface after removing the protective film.

- Easy to install, uniform thickness, and suitable for quick applications.

👉 Ideal for roofs, terraces, and water tanks.

4. Torch Applied Bitumen Membrane

- In this method, bitumen sheets are heated with a blowtorch while being rolled on the surface.

- Heat melts the underside of the sheet, which bonds strongly with the surface.

- Provides excellent waterproofing and long-term durability.

👉 Commonly used on flat roofs and exposed surfaces.

5. Bituminous Coating (Protective Paint)

- Also called asphalt coating, it is a thin liquid form applied like paint.

- Provides protective waterproofing for foundations, pipes, and metal surfaces.

👉 Best suited for damp proofing below ground level.

Bitumen Waterproofing Process

A waterproofing system is only as good as its application. Even the best quality bitumen can fail if the process is not done properly. Below is a step-by-step process followed in most projects:

1. Surface Preparation

- Clean the surface thoroughly by removing dust, grease, oil, or loose particles.

- Repair cracks, holes, or uneven areas with mortar or filler.

- Make sure the surface is completely dry before application.

👉 A well-prepared surface ensures maximum bonding strength.

2. Primer Application

- Apply a coat of bitumen primer with a brush, roller, or spray.

- The primer seals pores, reduces surface absorption, and improves adhesion.

- Allow the primer coat to dry for a few hours before moving to the next step.

3. Application of Bitumen Layer or Membrane

This is the most important stage of the process, because here the actual waterproofing barrier is created. Depending on the method chosen, bitumen can be applied in different ways:

Hot Applied Bitumen

- Bitumen is heated in a boiler or tar kettle until it becomes a thick liquid.

- The hot bitumen is poured or spread directly on the surface using a mop, brush, or sprayer.

- While still hot, reinforcement layers (like roofing felt or fiber mat) can be embedded for extra strength.

👉 Advantage: Seamless coating with excellent bonding.

👉 Precaution: Requires skilled labor and safety measures due to high temperature.

Cold Applied Bitumen (Bitumen Emulsion)

- Ready-to-use liquid form, applied directly with brush, roller, or spray.

- After application, the water in the emulsion evaporates, leaving behind a waterproof bitumen film.

- Multiple coats are usually applied to achieve the required thickness.

👉 Advantage: Safe, easy to use, no heating required.

👉 Precaution: Needs sufficient drying time between coats.

Self-Adhesive Bitumen Membranes

- Sheets made of bitumen with a sticky adhesive backing and protective film.

- The film is peeled off, and the sheet is pressed firmly onto the primed surface.

- Overlaps of about 75–100 mm are maintained between sheets to ensure leak-proof joints.

👉 Advantage: Fast installation, uniform thickness.

👉 Precaution: Surface must be perfectly clean and smooth for proper adhesion.

Torch Applied Bitumen Membranes

- Sheets of modified bitumen are rolled over the surface.

- A blowtorch is used to heat the underside of the sheet, melting the bitumen.

- The melted bitumen fuses with the primed surface, creating a strong bond.

- Overlaps are also torched to seal joints completely.

👉 Advantage: Highly durable, ideal for flat roofs and exposed areas.

👉 Precaution: Requires trained applicators; fire safety must be ensured.

👉 Each method requires uniform coverage and proper overlap of joints.

4. Sealing of Joints and Critical Areas

- Extra care is taken at corners, edges, and overlaps.

- Additional bitumen coating or extra membrane strips are applied to seal weak spots.

- This prevents leakage at vulnerable points.

5. Protective Finishing Layer (Optional but Recommended)

- A layer of tiles, screed, or aluminum paint can be added over the waterproofing.

- Protects the bitumen from UV rays, mechanical damage, and weathering.

👉 Extends the life of the waterproofing system.

Best Practices for Long-Lasting Waterproofing

- Ensure the surface is fully dry before application.

- Maintain the recommended thickness of coating/membrane.

- Use skilled labor, especially for torch-on membranes.

- Allow proper curing/drying time before water exposure.

- Always follow the manufacturer’s guidelines for material usage.

Advantages of Bitumen Waterproofing

Bitumen waterproofing is a popular choice in the construction industry because it offers several benefits. Here are the key advantages:

1. Strong Waterproofing Protection

- Bitumen waterproofing creates a dense and continuous barrier that blocks water completely.

- It effectively prevents leakage, dampness, and corrosion of steel reinforcement inside concrete.

2. Long-Lasting Durability

- When applied correctly, bitumen waterproofing can last 10–15 years or more with minimal maintenance.

- It performs well even in harsh climates, heavy rains, and extreme heat.

3. Excellent Adhesion to Surfaces

- Bitumen has adhesive properties, so it sticks firmly to concrete, brick, stone, wood, and metal.

- This strong bonding ensures that the waterproofing layer does not peel off or detach easily.

4. Flexibility and Crack Resistance

- Bitumen membranes can expand and contract with thermal movements of the structure.

- This flexibility helps in resisting small cracks and structural movements, reducing the chances of leakage of water.

5. Cost-Effective Solution

- Compared to advanced systems like polyurethane or epoxy coatings, bitumen is more affordable.

- It provides reliable waterproofing at a lower price, making it suitable for residential as well as large infrastructure projects.

Disadvantages / Hidden Risks of Bitumen Waterproofing

While bitumen waterproofing offers many benefits, it also has some drawbacks that cannot be ignored. Knowing these limitations helps in deciding whether it is the right choice for your project.

1. Heat Sensitivity

- Bitumen reacts strongly to temperature changes.

- In hot climates, it can soften, flow, or lose shape, leading to surface damage.

- In cold climates, it becomes brittle and may crack.

👉 That’s why exposed bitumen surfaces always require a protective layer such as screed, tiles, or aluminum coating.

2. Shorter Life Compared to Advanced Systems

- Bitumen membranes usually last 10–15 years, provided they are well-maintained.

- Modern alternatives like PVC membranes, EPDM sheets, or polyurethane coatings can last 20–30 years.

👉 This means structures relying only on bitumen may need early replacement, which adds to the lifecycle cost.

3. Requires Skilled Installation

- Methods like torch-on membranes or hot-applied coatings require expert applicators.

- If applied by untrained workers, common problems include:

- Air bubbles beneath the sheet

- Poor overlaps between joints

- Uneven thickness of coating

👉 These issues often result in leakage within a few years, even if good material is used.

4. Environmental Concerns

- Bitumen is a petroleum-based product, making it less sustainable.

- During hot application, it releases fumes that can affect workers’ health if safety measures are not followed.

- Disposal of old bitumen sheets is also an environmental challenge.

5. Regular Maintenance Needed

- Bitumen is not a “fit and forget” material.

- If left exposed, UV rays from sunlight cause it to crack, peel, and lose flexibility.

- Protective topping (tiles, screed, or paint) is often necessary to extend its life.

Applications of Bitumen Waterproofing in Construction

Bitumen waterproofing is used in almost every type of structure — from small houses to large infrastructure projects. Its versatility and cost-effectiveness make it one of the most preferred solutions. Here are some of these applications listed below:

1. Roofs

- Flat roofs are highly vulnerable to water ponding and leakage. Bitumen membranes (torch-on or self-adhesive) provide a seamless waterproofing barrier.

- In sloped roofs, bitumen is applied under tiles or shingles to give extra protection against rainwater.

👉 Common in residential houses, commercial complexes, and industrial sheds.

2. Basements and Foundations

- Basements and underground structures are always in contact with soil moisture.

- Bitumen coatings or membranes applied on outer walls and foundation slabs protect against water seepage and dampness.

👉 Helps in keeping basements dry, usable, and free from fungal growth.

3. Damp Proof Course (DPC)

- A horizontal layer of bitumen applied at the plinth level prevents rising damp (capillary water) from the soil into the walls.

- Without DPC, moisture travels upward, damaging plaster, paint, and even electrical fittings, so a thin layer of bitumen waterproofing matter coat on the plinth level to protect it.

👉 Bitumen DPC is still one of the most reliable methods in residential construction.

4. Bridges and Tunnels

- Heavy-duty torch-applied membranes are commonly used in bridges, flyovers, and tunnels.

- They protect concrete decks and reinforcement steel from water infiltration.

👉 Ensures the long life of critical infrastructure and reduces maintenance costs.

5. Water Tanks and Reservoirs

- Bitumen coatings and membranes are used to waterproof overhead and underground water tanks, reservoirs, and sumps.

- Prevents leakage and contamination from external water sources.

👉 Especially useful in municipal water storage systems.

6. Bathrooms, Kitchens, and Wet Areas

- Cold-applied bitumen emulsions type bitumen waterproofing is applied below tiles in bathrooms, kitchens, and balconies.

- Protects floor slabs from seepage and leakage into lower floors.

👉 Very common in residential apartments and multi-storey buildings.

7. Industrial and Commercial Floors

- Bitumen waterproofing materials are applied to factory floors, parking decks, and warehouses.

- Protects concrete from water, chemicals, oil spills, and heavy vehicular loads.

👉 Widely used in industrial construction projects.

Cost of Bitumen Waterproofing in India

The cost of bitumen waterproofing in India depends on various factors such as the type of system used, the area of application, and labor charges. On average, the price is considered affordable compared to modern waterproofing methods.

Average Cost Range

- Bitumen Coating (Cold/Hot Applied): ₹25 – ₹60 per sq. ft.

- Self-Adhesive Membranes: ₹60 – ₹120 per sq. ft.

- Torch Applied Membranes (SBS/APP modified): ₹80 – ₹150 per sq. ft.

- DPC Layer with Bitumen: ₹20 – ₹40 per sq. ft.

👉 These are approximate costs and can vary based on location, brand, thickness, and labor quality.

Bitumen Waterproofing vs Alternatives

While bitumen waterproofing is popular, it is not the only method available for waterproofing. Modern waterproofing systems like cementitious coatings, liquid membranes, PVC sheets, and polyurethane are also widely used. Here’s how bitumen compares with its alternatives tabled below:

| Method | Advantages | Disadvantages | Best uses For |

|---|---|---|---|

| Bitumen Waterproofing | Strong adhesion, durable, cost-effective, versatile applications | Lifespan 10–15 years, heat sensitive, needs skilled labor, not eco-friendly | Large areas, cost-sensitive projects, basements, bridges, DPC, foundations |

| Cementitious | Easy to apply, low cost, widely available | Less flexible, prone to cracking with movement | Bathrooms, kitchens, water tanks, internal wet areas |

| Liquid Membranes (Acrylic/PU) | High-end projects, terraces, exposed concrete, and chemical plants | More expensive, requires skilled applicators | Roofs, terraces, exposed areas needing flexibility + good finish |

| PVC/EPDM/HDPE Sheets | Very durable, long life (20–30 years), UV & chemical resistant | High initial cost, expert installation needed | Industrial sheds, commercial roofs, premium projects |

| Polyurethane Coatings | Highly elastic, long life, chemical resistant, seamless | Costly, sensitive to surface moisture during application | High-end projects, terraces, exposed concrete, chemical plants |

Read more Civil Engg topics

- Chlorination of water

- Difference between bitumen and tar

- Pile foundation

- Drip Irrigation

- Viscosity

- Surface Tension

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Bituminous concrete

Conclusion

Bitumen waterproofing is one of the oldest and most reliable methods used in construction. It provides strong protection against water seepage, has good adhesion, and is affordable compared to many modern systems. From roofs and basements to bridges and DPC layers, its applications are vast and time-tested.

However, it is not without drawbacks. Being a petroleum-based product, bitumen is heat-sensitive, less eco-friendly, and requires skilled installation. Over time, it may lose flexibility and develop cracks if not properly protected or maintained.

So, is bitumen waterproofing the best protection or a hidden risk?

👉 The answer is: It can be the best protection if applied correctly, protected with a finishing layer, and maintained regularly. But if ignored or poorly installed, it may turn into a hidden risk for your structure.

For cost-sensitive projects and general construction, bitumen waterproofing remains a practical choice. For critical structures where long life and zero maintenance are priorities, modern alternatives like PVC, polyurethane, or liquid membranes may be better.

FAQs on Bitumen Waterproofing

1. What is bitumen waterproofing used for?

It is used to protect roofs, basements, foundations, DPC, and tanks from water leakage.

2. How long does bitumen waterproofing last?

On average, it lasts 10–15 years with proper installation and maintenance.

3. Is bitumen waterproofing good for roofs?

Yes, it is highly effective for both flat and sloped roofs.

4. What are the disadvantages of bitumen waterproofing?

Shorter lifespan, heat sensitivity, and the need for skilled labor are its main drawbacks.

5. How much does bitumen waterproofing cost in India?

It costs around ₹25–₹150 per sq. ft., depending on type and location.

6. Which is better – bitumen waterproofing or liquid membrane?

Bitumen is cost-effective, while liquid membranes are more durable and flexible.

Final Words

Bitumen waterproofing is still one of the most reliable and affordable solutions for protecting structures against water damage. But remember, correct application and timely maintenance are the keys to making it last longer.

If you found this guide helpful, don’t forget to check out our related articles on Bitumen:

Thank you 🙏 for reading this article. We hope it helped you understand the basics of bitumen waterproofing in a simple way. Stay tuned with Civil Weda for more useful guides on civil engineering topics. Your support motivates us to keep sharing valuable content.