Introduction

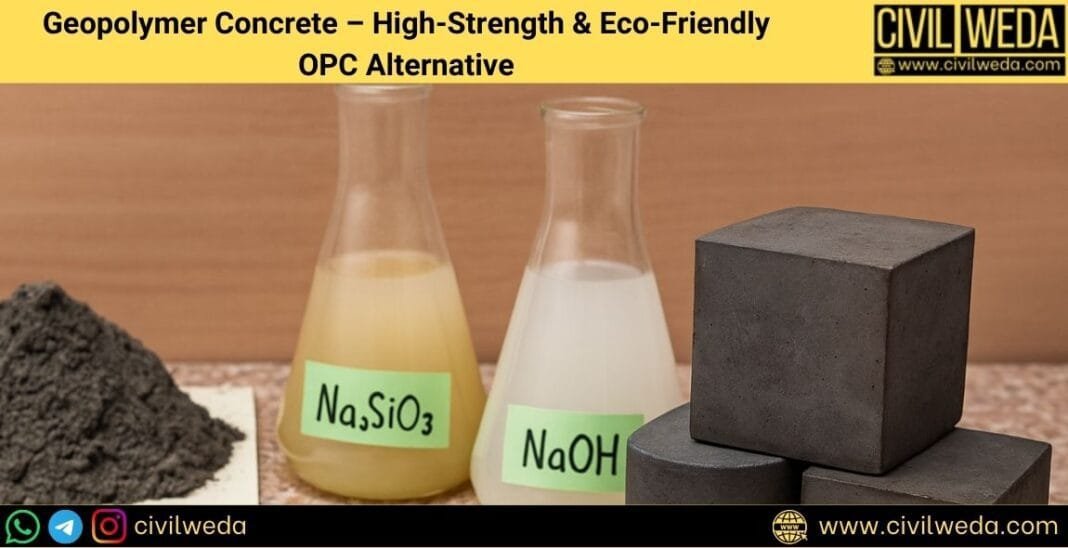

Concrete stands as the dominant material in the field of construction due to its versatility and availability. Whether it is a small residential building or a massive flyover, dam, or bridge structure, ordinary Portland cement (OPC) concrete has always been the first choice. Cement manufacturing industries contribute around 7–8% of the total global carbon dioxide (CO₂) emissions, which is a serious environmental issue. To address this issue, civil engineers and researchers have been working on alternative materials that are both sustainable and durable. One such promising solution is Geopolymer Concrete (GPC).

Instead of cement, geopolymer concrete utilises industrial by-products such as fly ash and GGBS (Ground Granulated Blast Furnace Slag), which are activated with alkaline solutions. Because of its ability to utilise industrial waste and reduce the emission of CO₂, geopolymer concrete is often described as a form of ‘Green concrete’.

What is Geopolymer Concrete?

Geopolymer concrete can be defined as a cement-free type of concrete in which waste materials such as fly ash and blast furnace slag act as the main binding ingredients. The main characteristic of these materials is their richness in silica and alumina, which play a crucial role in the formation of the binding gel. When they are mixed with alkaline solutions such as sodium hydroxide (NaOH ) and sodium silicate (Na₂SiO₃), a chemical reaction takes place known as polymerisation.

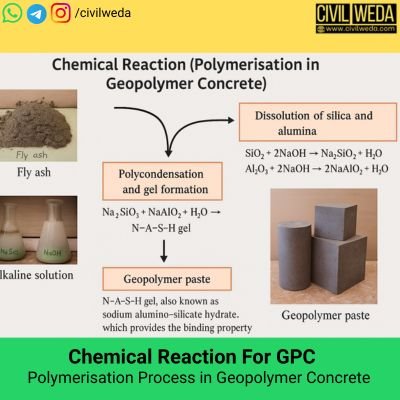

This reaction produces a binding gel that holds aggregates (fine and coarse aggregates) together, just like cement paste in ordinary cement concrete. The overall geopolymerisation process mainly involves three stages: dissolution, polycondensation, and gel formation.

The chemical reactions can be represented as follows:

Dissolution of silica and alumina

SiO₂ + 2NaOH → Na₂SiO₃ + H₂O

Al₂O₃ + 2NaOH → 2NaAlO₂ + H₂O

Polycondensation and gel formation

Na₂SiO₃ + NaAlO₂ + H₂O → N–A–S–H gel

N–A–S–H gel, also known as sodium alumino-silicate hydrate, which provides the binding property

This ‘sodium alumino-silicate hydrate’ gel has a binding property that binds the fine and coarse sand together.

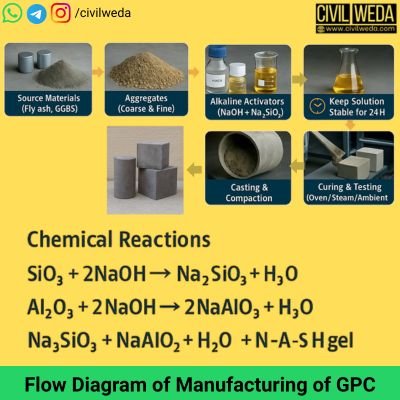

Manufacturing of Geopolymer Concrete

The manufacturing of geopolymer concrete differs slightly from that of ordinary Portland cement concrete, as it involves alkaline activators instead of cement. The process is explained step by step with a flow diagram as shown below:

Materials used in Geopolymer Concrete Manufacturing

Raw Or Source Material:

Fly ash, GGBS, or other alumino-silicate-rich materials are selected.

Aggregates:

Coarse and fine aggregates are similar to conventional concrete, like OPC.

Learn more about the Bulking of Sand and its effect on fine and coarse aggregates.

Alkaline Activators:

To initiate the polymerisation process, geopolymer concrete requires alkaline activators. Typically, sodium hydroxide (NaOH) provides the necessary alkalinity, while sodium silicate (Na₂SiO₃) enhances the dissolution of alumino-silicate materials

Water:

Used in small quantities to enhance the workability of concrete (GPC).

Preparation of Alkaline Solution

- Sodium hydroxide pellets are dissolved in water.

- Sodium silicate solution is then mixed with sodium hydroxide solution.

- This activator solution is prepared at least 24 hours before mixing to allow for stabilisation.

Mixing of Ingredients

- The source material (fly ash/GGBS) is dry mixed with aggregates (fine and coarse aggregates).

- The prepared alkaline solution is slowly added to the dry mix.

- Water: Added in controlled amounts to achieve the desired workability of the mix.

- Mixing continues until a uniform consistency is obtained.

Casting of Specimens

- The fresh geopolymer concrete is placed into moulds (such as cubes, cylinders, or structural formwork).

- Mechanical vibration is used to remove air voids and ensure proper compaction.

Curing of Geopolymer Concrete

Geopolymer concrete differs from OPC concrete in that it develops strength without the need for traditional water curing methods. Instead, curing is achieved through:

- Oven Curing: The concrete is kept in an oven at 60–90°C for 24 hours or more.

- Steam Curing: Steam chambers at elevated temperatures are used.

- Ambient Curing: In some cases, geopolymer concrete can harden at room temperature, but the strength development is slower compared to heat curing

Final Strength Development

- After curing, geopolymer concrete continues to gain strength over the period of time.

- Depending on the mix design, it can achieve compressive strengths of 60–80 MPa or more.

Properties of Geopolymer Concrete

- High Compressive Strength – GPC can achieve compressive strengths up to 60–100 MPa, depending on the mix.

- Low Shrinkage and Creep – Better dimensional stability compared to OPC concrete.

- High Durability – Excellent resistance against sulphate attack, chloride penetration, and chemical corrosion.

- Faster Setting Time – Similar to rapid hardening cement, Geopolymer concrete sets faster, allowing quick strength gain at early ages..

- Fire Resistance – In comparison to OPC concrete, GPC shows superior performance when exposed to elevated temperatures.

- Low Permeability – Better resistance to water absorption.

Advantages of Geopolymer Concrete

- Eco-Friendly – Up to 80% reduction in CO₂ emissions compared to OPC concrete.

- Waste Utilisation – Uses fly ash and GGBS, which are by-products of thermal power plants and steel industries.

- High Strength and Durability – Suitable for aggressive environments.

- Better Performance in Fire – Retains structural integrity at higher temperatures.

- Fast Strength Development – Useful for precast industries.

- Long-Term Cost Benefits – Although the raw materials are slightly more expensive, it prove cost-effective in the long run due to reduced maintenance needs.

Disadvantages of Geopolymer Concrete

- Cost of Alkaline Activators – Sodium hydroxide and sodium silicate are relatively expensive.

- Lack of Standard Codes – Limited guidelines in IS codes for mass adoption.

- Skilled Labour Requirement – Needs knowledge of handling chemical solutions.

- Special Curing Requirement – Oven or steam curing may not be feasible for large projects.

- Limited Field Experience – More research is needed for large-scale construction.

Applications of Geopolymer Concrete

In structural applications such as beams and slabs, understanding parameters like effective span is important when using advanced concretes like GPC compared to OPC

- Pavements and Roads – Quick repairs with early strength

- Precast Elements – Beams, sleepers, pipes (controlled curing possible)

- Marine and Chemical Structures – Excellent chemical resistance

- High-Temperature Applications – Fire-resistant structures

- Green Buildings – Sustainable construction projects

Comparison between Geopolymer Concrete (GPC) and Ordinary Portland Cement Concrete (OPC)

While plain cement concrete is widely used, its disadvantages, like high CO₂ emissions, lower tensile strength and low durability, make GPC a promising alternative, and a Comparison between Geopolymer Concrete (GPC) and Ordinary Portland Cement Concrete (OPC) is listed below:

| Property | Geopolymer Concrete | Ordinary Portland Cement Concrete |

| Binder Material | Fly ash, GGBS + alkaline | Cement (OPC) |

| CO₂ Emission | Very Low (up to 80% less) | Very High |

| Strength | High (60–100 MPa possible) | Moderate (20–50 MPa typical) |

| Durability | Excellent | Moderate |

| Resistance to Chemicals | High | Moderate |

| Fire Resistance | Very Good | Limited |

| Cost | Slightly High | Moderate |

| Standard Codes | Limited | Well-established |

Future Scope of Geopolymer Concrete

- Development of Codes & Standards: IS and ASTM codes are being worked on.

- Wider Industrial Adoption: Power plants and steel industries can directly supply waste materials.

- Smart Concrete: Integration with nanomaterials can create self-healing and self-sensing concrete.

- Sustainability Goals: Governments are encouraging eco-friendly construction under climate change policies.

Overall, geopolymer concrete is recognised as a sustainable construction material that aligns with global goals for carbon-neutral construction.

Read more Civil Engg topics

- Chlorination of water

- Per Capita Water Demand

- Pile foundation

- Drip Irrigation

- Viscosity

- Surface Tension

- Instrument used in a chain survey

- Fillet Weld

Conclusion

Geopolymer concrete is one of the most promising innovations in modern civil engineering.

It effectively tackles two major challenges: reducing the carbon footprint of cement production and utilising industrial by-products such as fly ash and GGBS.

By replacing ordinary Portland cement with geopolymeric binders, it significantly reduces CO₂ emissions, improves durability, and offers high compressive strength suitable for harsh environments.

With proper mix design and curing methods, geopolymer concrete can achieve exceptional performance even in aggressive chemical and high-temperature conditions.

However, for its large-scale adoption, challenges such as the higher cost of alkaline activators, lack of standard IS codes, and the need for trained labour must be addressed.

FAQs on Geopolymer Concrete

1. Why is geopolymer concrete referred to as green concrete?

Geopolymer concrete is referred to as ‘green concrete’ because it drastically reduces CO₂ emissions compared to OPC concrete and promotes sustainability by using industrial waste materials such as fly ash and GGBS.

2. What are the main raw materials of geopolymer concrete?

The primary raw materials used in geopolymer concrete include industrial by-products such as fly ash, ground granulated blast furnace slag (GGBS), and, in some cases, rice husk ash. To activate these alumino-silicate-rich materials, alkaline solutions like sodium hydroxide (NaOH) and sodium silicate (Na₂SiO₃) are employed.

3. Is geopolymer concrete cheaper than ordinary concrete?

Initial material cost is slightly higher, but due to durability and low maintenance, it is cost-effective in the long run.

4. Can geopolymer concrete be used for all structures?

Yes, but curing requirements and a lack of standard codes limit its universal application.

5. What is Polymerisation?

Polymerisation is the chemical reaction in which the silica (SiO₂) and alumina (Al₂O₃) present in fly ash, GGBS, or other industrial by-products react with an alkaline activator to form a strong binding gel.

6. What is the compressive strength of geopolymer concrete?

It can easily reach 60–100 MPa, which is higher than conventional OPC concrete.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Geopolymer Concrete in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀