Introduction

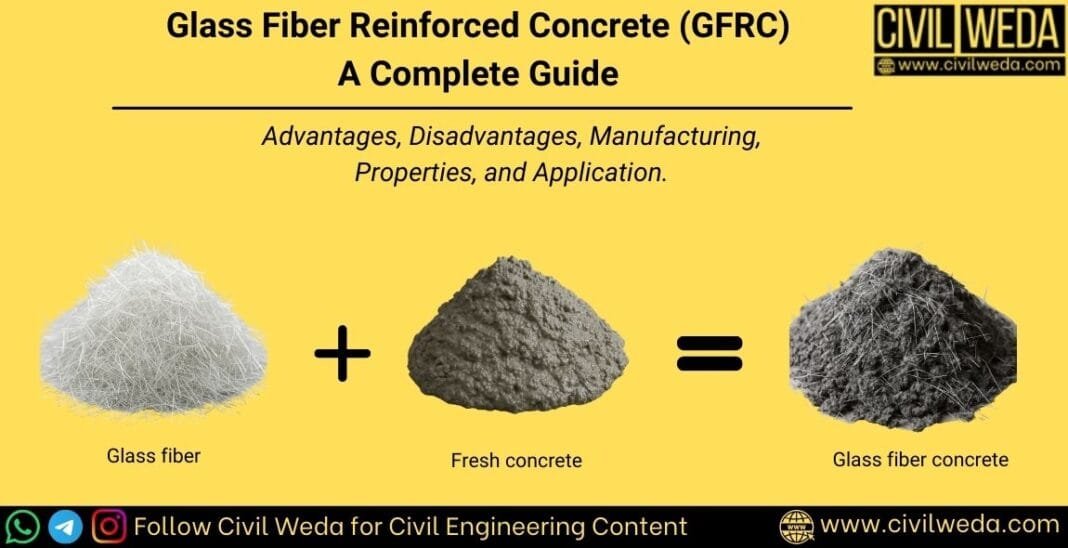

Concrete has long been the backbone of the construction industry due to its strength, durability, and versatility. However, traditional concrete faces certain limitations such as heavy self-weight, low tensile strength, and limited design flexibility. These challenges led researchers and engineers to explore advanced composite materials. Among the most successful innovations is (GFRC) Glass Fiber Reinforced Concrete.

Glass Fiber Reinforced Concrete is a modern composite made of cement, fine aggregates, polymers, water, and alkali-resistant glass fibers. The presence of glass fibers transforms concrete into a lightweight, ductile, and highly durable material. Unlike conventional reinforced concrete, which depends on steel reinforcement, Glass Fiber Reinforced Concrete utilizes uniformly dispersed glass fibers to significantly enhance tensile and flexural performance.

Today, GFRC is extensively used in architectural cladding, decorative elements, façades, and precast components. Its versatility, superior aesthetics, and long service life make it one of the most important alternatives to traditional concrete. This article provides a complete guide to GFRC—covering its history, composition, manufacturing process, properties, advantages, disadvantages, applications, comparison with other concretes, sustainability aspects, and future scope.

History and Development of Glass Fiber Reinforced Concrete

The idea of using fibers to make concrete stronger is not new. In fact, people experimented with natural fibers like straw and horsehair in clay and mortar thousands of years ago. However, those materials were not durable and could not survive in the alkaline environment of cement.

A major breakthrough came in the 1960s and 1970s, when scientists developed alkali-resistant (AR) glass fibers by adding zirconia. These special fibers could withstand the alkalinity of cement, making them reliable for reinforcing concrete.

After this discovery, Glass Fiber Reinforced Concrete became popular in Europe and North America, especially for making architectural panels and cladding systems. With time, the technology improved further with the use of better polymers, curing methods, and spraying equipment. Today, GFRC is a well-established material with applications all over the world.

Composition of Glass Fiber Reinforced Concrete

Glass Fiber Reinforced Concrete is made by combining several ingredients in proper proportions. Each material plays an important role in improving the overall performance of concrete:

- Cement

- Ordinary Portland Cement (OPC) or Sulphate-Resistant Cement is commonly used.

- It acts as the primary binder, holding all materials together and providing strength.

- Ordinary Portland Cement (OPC) or Sulphate-Resistant Cement is commonly used.

- Fine Aggregates (Sand)

- Clean, well-graded silica sand is preferred.

- It increases density, reduces shrinkage, and improves the durability of the mix.

- Clean, well-graded silica sand is preferred.

- Water

- Potable, clean water is essential.

- The water-to-cement ratio is usually kept between 0.35–0.45 to balance strength and workability.

- Potable, clean water is essential.

- Polymer Admixtures

- Acrylic polymers and silica fume are often added.

- They enhance bonding, improve workability, and increase long-term durability.

- Acrylic polymers and silica fume are often added.

- Alkali-Resistant Glass Fibers (AR Fibers)

- The most important component of GFRC.

- Typically 10–50 mm in length and added in the proportion of 3–5% by weight of cement.

- These fibers significantly improve tensile and flexural strength while also providing resistance to cracking.

- The most important component of GFRC.

Manufacturing Process of Glass Fiber Reinforced Concrete

The production of GFRC Concrete involves several specialized techniques. Each method is chosen depending on the type of product and its application.

- Spray-Up Process

- A slurry of cement, sand, water, and admixtures is sprayed into prepared molds.

- At the same time, chopped glass fibers are sprayed using a special spray gun.

- Several layers are applied and compacted with rollers to remove air voids.

- This process is commonly used for large architectural cladding panels due to its high strength and uniform fiber distribution.

- A slurry of cement, sand, water, and admixtures is sprayed into prepared molds.

- Premix Process

- In this method, glass fibers are directly mixed into the slurry of cement, sand, and admixtures.

- The mixture is then poured or sprayed into molds.

- It is best suited for decorative items, thin elements, and components with complex shapes.

- In this method, glass fibers are directly mixed into the slurry of cement, sand, and admixtures.

- Hybrid Process

- A combination of both the spray-up and premix techniques.

- Offers more flexibility and is used when both strength and detailed shapes are required.

- A combination of both the spray-up and premix techniques.

- Curing

- Curing is a critical step in GFRC production.

- Moist curing for at least 7 days, or polymer curing, is applied to ensure complete hydration.

- Proper curing improves durability, crack resistance, and long-term strength of GFRC products.

- Curing is a critical step in GFRC production.

Properties of Glass Fiber Reinforced Concrete

GFRC concrete exhibits a unique set of properties that make it superior to conventional concrete in many applications. These can be classified into different categories:

Mechanical Properties

- Compressive Strength: Ranges between 50–80 MPa, comparable to or even higher than traditional concrete.

- Flexural Strength: About 10–25 MPa, much higher than ordinary concrete due to fiber reinforcement.

- Tensile Strength: Significantly improved, as dispersed glass fibers carry tensile stresses effectively.

- Impact Resistance: Excellent, since fibers absorb energy and prevent brittle failure.

Physical Properties of Glass Fiber Reinforced Concrete

- Density: Around 1800–2000 kg/m³, making GFRC lighter than normal concrete (2300–2500 kg/m³).

- Low Permeability: High resistance to water and moisture penetration.

- Surface Finish: Very smooth and uniform, ideal for architectural and decorative elements.

Durability Properties of

- Resistant to freeze–thaw cycles in cold climates.

- Provides good fire resistance.

- Highly resistant to corrosion, weathering, and chemical attack.

- Ensures a long service life with minimal deterioration.

Additional Properties

- Thermal Insulation: Helps improve energy efficiency in cladding applications.

- Acoustic Insulation: Provides better sound absorption in certain applications.

- Aesthetic Versatility: Can be cast in a wide range of textures, colors, and patterns.

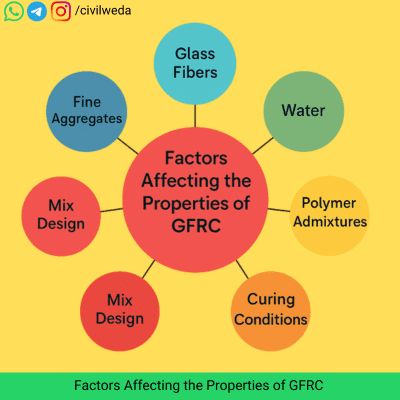

Factors Affecting the Properties of GFRC

The performance of Glass Fiber Reinforced Concrete (GFRC) is not determined only by its raw materials but also by several external and processing factors. Several factors play a crucial role in defining the properties of GFRC.

1. Type and Content of Glass Fibers

- The length (10–50 mm) and percentage (3–5% by weight of cement) of fibers directly influence strength and crack resistance.

- Too few fibers reduce strength, while excessive fibers may lower workability.

2. Fiber Orientation and Distribution

- Uniform fiber distribution increases flexural strength.

- Random distribution improves impact resistance and crack control.

3. Water-to-Cement Ratio

- A low w/c ratio enhances compressive and flexural strength.

- A high w/c ratio increases shrinkage and permeability.

4. Type of Polymer Admixtures

- Acrylic polymers and silica fume enhance bonding and durability.

- Polymer dosage also affects curing behavior and surface smoothness.

5. Curing Method and Duration

- Proper moist curing (minimum 7 days) helps achieve long-lasting strength and durability.

- Inadequate curing can lead to shrinkage cracks and early deterioration.

6. Manufacturing Technique

- The spray-up method provides uniform fiber distribution and higher strength.

- The premix method is better for thin and decorative elements.

7. Environmental Conditions

- High temperatures accelerate curing but may increase shrinkage.

- Freeze–thaw cycles are critical in assessing durability.

Advantages of Glass Fiber Reinforced Concrete

- High Strength – Provides excellent tensile and flexural strength compared to normal concrete.

- Lightweight – Reduces dead load on the structure, making it ideal for cladding and precast elements.

- Durable and Fire Resistant – Performs well under harsh weather conditions and resists fire damage.

- Low Maintenance – Requires minimal upkeep during its service life.

- Superior Aesthetics – Offers smooth surface finish, different textures, and high design flexibility.

- Thin Sections Possible – Can be cast into panels as thin as 10–15 mm without losing strength.

- Long Service Life – Reduces repair and replacement costs over time.

- Chemical and Environmental Resistance – Performs well in marine, industrial, and polluted environments.

Disadvantages of Glass Fiber Reinforced Concrete

- High Cost – Usually 2–3 times more expensive than conventional concrete.

- Skilled Labor Required – Needs trained workers and specialized equipment for mixing and installation.

- Limited Material Availability – Alkali-resistant glass fibers and polymers may not be easily available everywhere.

- Strict Quality Control – Proper mixing and curing conditions are essential for desired performance.

- Non-Structural Use – Generally not suitable for heavy load-bearing structural elements.

Applications of Glass Fiber Reinforced Concrete

- Architectural Cladding Panels

- GFRC is extensively used in cladding systems for modern buildings, commercial complexes, and high-rise structures.

- Its lightweight nature reduces the dead load on buildings, while providing durable and aesthetically pleasing façades.

- GFRC is extensively used in cladding systems for modern buildings, commercial complexes, and high-rise structures.

- Decorative and Ornamental Elements

- GFRC is ideal for fountains, sculptures, railings, columns, cornices, and garden planters.

- It can be easily molded into complex and detailed shapes, offering smooth finishes and long-lasting durability.

- GFRC is ideal for fountains, sculptures, railings, columns, cornices, and garden planters.

- Infrastructure Projects

- Widely adopted in precast bridge elements, pavements, retaining walls, and acoustic barriers along highways.

- Its strength and resistance to environmental factors make it suitable for long-term infrastructure use.

- Widely adopted in precast bridge elements, pavements, retaining walls, and acoustic barriers along highways.

- Marine and Industrial Structures

- GFRC is resistant to saltwater, chemicals, and harsh weather conditions, making it highly effective in marine environments such as ports and harbors.

- In industrial areas, GFRC panels and elements withstand exposure to pollutants and corrosive chemicals.

- GFRC is resistant to saltwater, chemicals, and harsh weather conditions, making it highly effective in marine environments such as ports and harbors.

Apart from GFRC, another widely used material in modern construction is Ready Mix Concrete (RMC), which ensures speed, quality, and consistency on site.

GFRC Concrete vs Traditional Concrete

| Property | GFRC Concrete | Traditional Concrete |

| Density | 1800–2000 kg/m³ (Lightweight) | 2300–2500 kg/m³ (Heavier) |

| Tensile Strength | High (due to glass fibers) | Very low (requires steel reinforcement) |

| Flexural Strength | 10–25 MPa | 3–5 MPa |

| Panel Thickness | Thin panels (10–15 mm) | Thicker panels (25–40 mm) |

| Cost | Higher (2–3× conventional) | Lower (economical) |

| Aesthetics | Excellent (textures, colors, shapes possible) | Limited options |

| Durability | Very high (weather & fire resistant) | Moderate (prone to cracks & degradation) |

GFRC Concretes vs Other Special Concretes

- GFRC vs FRC (Fiber Reinforced Concrete): GFRC uses glass fibers and is lightweight with better aesthetics; FRC often uses steel or polypropylene fibers and is mainly for structural strength.

- GFRC vs HPC (High Performance Concrete): GFRC is valued for aesthetics and lightweight design; HPC provides extremely high compressive strength for bridges and high-rise structures.

- GFRC vs SCC (Self-Compacting Concrete): GFRC requires spraying or premix methods; SCC flows easily without vibration and is used in heavily reinforced sections.

Environmental Benefits and Sustainability of GFRC Concrete

- Reduced Raw Material Use: GFRC panels are thinner than conventional concrete, which reduces the consumption of cement and aggregates.

- Energy Efficiency: Its lightweight nature lowers transportation costs and reduces installation energy.

- Durability: A long service life minimizes the need for frequent replacements, making it eco-friendly.

- Recycling Potential: Ongoing research is exploring the use of recycled glass fibers and industrial by-products in GFRC production to make it more sustainable.

For sustainable construction, alternatives like Geopolymer Concrete are also gaining popularity due to their low carbon footprint.

Future Scope of Glass Fiber Reinforced Concrete

- Use of Nanomaterials: Researchers are incorporating nanomaterials such as nano-silica to further improve mechanical properties.

- Eco-Friendly GFRC: Efforts are being made to develop sustainable mixes by using recycled fibers and waste materials.

- 3D Printing Applications: GFRC is being tested in advanced 3D printing technologies for creating customized building elements.

- Green Building Integration: With the rise of sustainable construction, GFRC is expected to play a major role in future green building projects worldwide.

Conclusion

GFRC Concrete (Glass Fiber Reinforced Concrete) has transformed modern construction by offering a balance of strength, durability, lightweight characteristics, and aesthetic flexibility. Its ability to form thin, detailed, and long-lasting panels makes it ideal for cladding, decorative components, and precast applications.

Although GFRC is more expensive than conventional concrete, its long-term benefits—such as reduced maintenance, higher durability, and superior performance—make it a cost-effective choice. With continuous innovations and sustainable practices, GFRC is poised to become a key material in the future of construction and architecture.

Frequently Asked Questions

Q1. What is Glass Fiber Reinforced Concrete used for?

GFRC is mainly used for cladding panels, facades, decorative elements, precast structures, and infrastructure applications.

Q2. How does GFRC Concrete differ from ordinary concrete?

GFRC contains alkali-resistant glass fibers, which improve tensile and flexural strength, reduce weight, and allow thinner panels compared to normal concrete.

Q3. What is the average strength of GFRC?

GFRC usually achieves a compressive strength of 50–80 MPa and a flexural strength of 10–25 MPa.

Q4. Is Glass Fiber Reinforced Concrete fire-resistant?

Yes. GFRC has excellent fire resistance due to its cementitious matrix and glass fiber reinforcement.

Q5. How long can Glass Fiber Reinforced Concrete panels last?

With proper curing, installation, and maintenance, GFRC panels can last more than 40–50 years.

Q6. What are the disadvantages of Glass Fiber Reinforced Concrete?

The main drawbacks are higher cost, the requirement of skilled labor, limited availability of raw materials, and strict curing needs.

Q7. Can Glass Fiber Reinforced Concrete be used structurally?

GFRC is mostly used for non-structural applications. However, ongoing research aims to expand its role in structural components.

Q8. What is the cost of GFRC in India?

The cost of GFRC cladding is generally 2–3 times higher than conventional concrete panels, depending on supplier, location, and design.

Q9. Is GFRC sustainable?

Yes. GFRC is considered sustainable because it requires fewer raw materials, has a long service life, and can incorporate recycled materials.

Q10. Which industries benefit most from Glass Fiber Reinforced Concrete?

The main industries include architecture, construction, infrastructure, marine engineering, and decorative product manufacturing.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Glass Fiber Reinforced Concrete in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀