Introduction

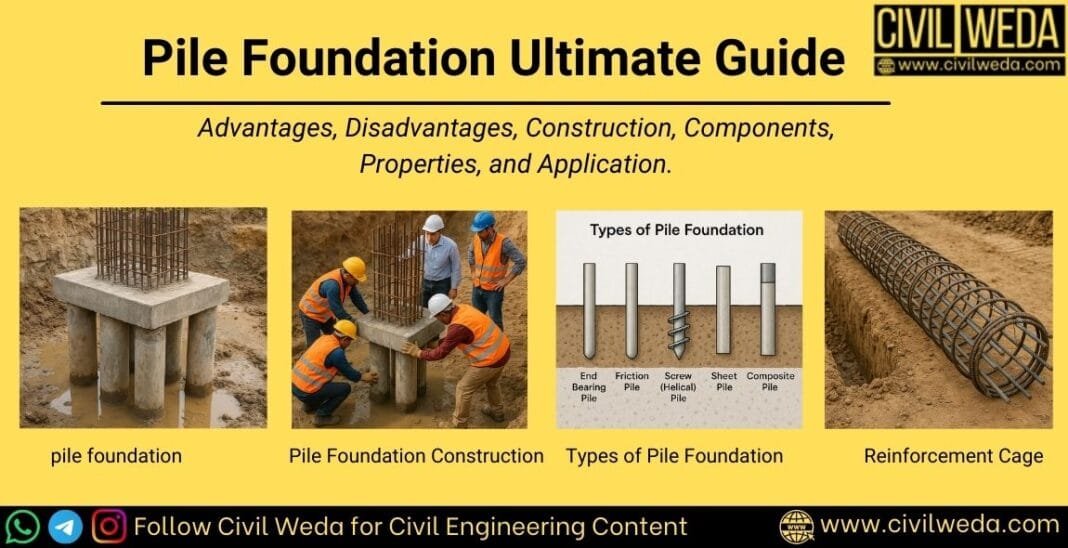

In any building or structure, the foundation is the base that carries the entire load. If the soil near the ground surface is soft or weak, it cannot bear the heavy weight of the structure. In such cases, engineers use pile foundations to transfer the load to deeper and stronger soil or rock layers.

A pile foundation is basically a long and slender column made of concrete, steel, or timber. These piles are driven or cast into the ground and help in safely carrying the load of the building. They also reduce settlement and provide stability even in weak soil conditions.

In this ultimate guide on pile foundation, we will learn about its types, components, pile caps, cost, and price in India, and the common mistakes that should be avoided during construction.

This guide is written in simple words so that civil engineering students, site engineers, and professionals can easily understand the importance and practical use of pile foundations.

What is a Pile Foundation?

A pile foundation is a type of deep foundation used when the soil near the surface is not strong enough to carry the load of a building or structure. In simple words, when the top soil is soft or weak, engineers transfer the load to deeper and stronger soil layers or hard rock by using piles.

A pile is a long, slender column usually made of concrete, steel, or timber. These piles are either driven into the ground using hammers or created inside a drilled hole by pouring concrete. The main purpose of a pile foundation is to carry the load of the structure and safely transfer it to a deeper level.

Pile foundations are commonly used for:

- High-rise buildings.

- Bridges and flyovers.

- Water tanks.

- Marine and coastal structures.

For Example, You Just Imagine building on soft clay. And if you use a shallow foundation, the house will settle unevenly. But if you use pile foundations, the load goes deep into stronger soil, making the structure safe and stable. Thus, pile foundations are the best choice when surface soil cannot support heavy loads.

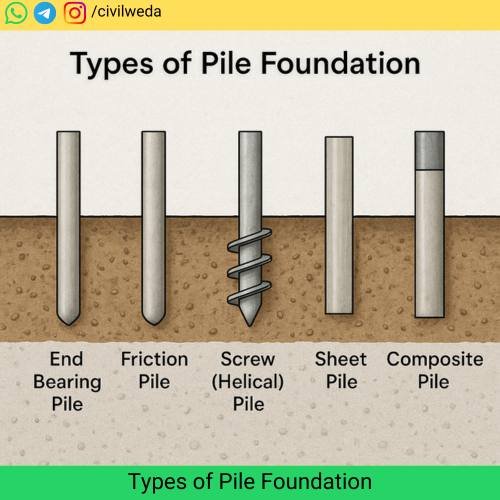

Types of Pile Foundations

Pile foundations are classified into different types depending on how they transfer load and how they are constructed. Below are the major types explained in simple language:

End Bearing Piles

- In this type, the pile acts like a column that transfers the load of the structure directly to a strong soil layer or hard rock.

- The pile toe (bottom) rests firmly on the hard strata, so the weak soil above does not affect the structure.

Example: Multi-storey buildings or bridges where rock is available at a certain depth.

Friction Piles

- These piles carry the load through skin friction between the surface of the pile and the surrounding soil.

- They are useful where no hard layer is available at a reasonable depth.

Example: High-rise buildings in clayey or sandy soil where end bearing is not possible.

Screw Piles / Helical Piles

- These piles are shaped like a screw and rotated into the ground.

- They are easy and quick to install, require less equipment, and can even be removed and reused.

Example: Light load structures, temporary sheds, solar farms, and areas with space restrictions.

Sheet Piles

- These are thin, interlocking sections (often made of steel or sometimes timber) that are driven into the ground.

- They are not used to carry building loads, but to retain soil or water.

Example: Retaining walls in deep excavations, riverbanks, and marine structures.

Composite Piles

- Made of more than one material, usually concrete with steel or timber with concrete.

They are strong, durable, and resistant to damage in difficult environments.

Example: Marine and coastal structures exposed to water and soil pressure.

Components of Pile Foundation

A pile foundation is made up of several key components. Each part has a specific role in transferring the loads from the structure to the deeper soil or rock. Let’s study them in detail:

Piles

- They are long, slender members of concrete, steel, or timber.

- Function: Carry the load of the building and transfer it to deeper, stronger soil or rock.

- Types of piles:

- End Bearing Piles – transfer load directly to rock.

- Friction Piles – use surface friction with soil.

- Screw/ Helical Piles – screw-shaped, fast installation.

- Importance: Without piles, the load cannot be safely carried to deeper strata.

Pile Cap

- Definition: A thick reinforced concrete slab resting on top of a group of piles.

- Function:

- Distributes the load evenly among all piles.

- Holds piles together as a single unit.

- Shapes: Rectangular, Trapezoidal, Circular, or Raft type, depending on Pile arrangement.

- Importance: Prevents unequal settlement by ensuring all piles share the load equally.

Pile Head

- Definition: The top portion of the pile that connects to the pile cap.

- Function:

- Transfers load from the pile cap to the pile.

- Provides a firm connection between the structure and the pile foundation.

- Construction Note: After pile installation, the top is trimmed to remove weak concrete and ensure proper load transfer.

Pile Toe

- Definition: The bottom end of the pile, which rests on soil or rock.

- Function:

- In end-bearing piles, the toe directly transfers load to rock.

- In friction piles, the toe helps to stabilize the pile in soil.

- Importance: Critical for ensuring piles stand firmly and resist buckling.

Reinforcement Cage

- Definition: A cage of steel bars inserted in bored or cast-in-situ piles.

- Function:

- Provides strength against bending, shear, and tension.

- Ensures ductility and prevents cracking.

- Importance: Increases the durability and load-carrying capacity of piles.

Pile Shoe

- Definition: A steel shoe or protective cover fixed at the toe of driven piles.

- Function:

- Helps piles penetrate hard soil layers.

- Protects the pile toe from damage during driving.

- Importance: Essential for driven piles used in dense or rocky soils.

Thus, A pile foundation is a combination of piles, pile cap, pile head, pile toe, reinforcement cage, and pile shoe. Each part has a crucial role in ensuring that the structure’s load is safely and efficiently transferred to the ground.

Pile Foundation Construction Process

The construction of a pile foundation is a systematic process. It involves planning, soil study, pile installation, pile cap construction, and quality testing. Below are the detailed steps:

Site Investigation and Soil Testing

- First, a geotechnical survey is carried out.

- Common tests: Standard Penetration Test (SPT), Cone Penetration Test (CPT), and borehole sampling.

- Purpose: to know

- Soil type (clay, sand, silt, rock)

- Bearing capacity of soil

- Depth of hard strata

- Based on this data, engineers decide the length, diameter, and type of piles required.

Pile Layout and Marking

- A layout is prepared according to the structural drawing.

- Pile positions are marked on the ground using a total station or a theodolite for accuracy.

- Even a small error in marking can lead to unequal load sharing between piles.

Pile Installation / Construction Methods

Depending on the type of pile, different construction techniques are used:

(a) Driven Piles

- Precast piles (concrete, steel, timber) are driven into the ground using:

- Drop hammer

- Diesel hammer

- Hydraulic hammer

- A pile shoe is often fixed at the toe to protect against damage.

- Advantages: Quick and strong.

- Limitation: Very noisy and causes vibrations (not suitable in cities).

(b) Bored Cast-in-Situ Piles

- A hole is drilled into the ground using a rotary rig or auger machine.

- A temporary casing or bentonite slurry is used to prevent hole collapse.

- A reinforcement cage is lowered into the borehole.

- Concrete is poured using a tremie pipe to avoid segregation.

- Advantages: Less noise, suitable for urban areas.

- Limitation: Slower compared to driven piles.

(c) Screw / Helical Piles

- Steel piles with helical blades are rotated into the soil like a screw.

- Fast and economical, no hammering required.

- Often used for temporary or light-load structures.

Trimming and Pile Head Preparation

- After pile installation, the top 50–150 mm of weak concrete is removed.

- Reinforcement bars are exposed and cleaned.

- Purpose: ensures strong bonding between the pile and pile cap.

Pile Cap Construction

- Excavation is done to the required depth around pile heads.

- Formwork and shuttering are placed.

- Reinforcement steel bars are tied as per design and connected with pile bars.

- Concrete is poured and vibrated to remove air voids.

- After curing, the pile cap becomes a rigid base connecting all piles.

Quality Control and Testing of Piles

Ensuring quality is the most critical part. Some tests include:

- Pile Integrity Test (PIT): Checks for cracks or voids inside piles.

- Dynamic Load Test: Performed during pile driving to estimate bearing capacity.

- Static Load Test: Actual load is applied to check safe capacity.

- Routine Tests: Checking alignment, verticality, and concrete quality.

Curing and Final Finishing

- Pile cap and pile head concrete are cured for at least 7–14 days (sometimes 28 days for full strength).

- Proper curing ensures durability and prevents cracks.

Precautions During Construction

- Maintain pile verticality within tolerance (1–2%).

- Ensure correct reinforcement placement and anchorage.

- Avoid segregation of concrete during pouring.

- Keep minimum pile spacing (2.5–3 times pile diameter) to prevent soil overlap.

- Follow strict safety measures during pile driving or boring.

In Simple Words, the pile foundation construction process includes which is tabled below:

| Step | Purpose |

|---|---|

| Soil Testing | Know the ground condition and soil type. |

| Marking | Fix exact pile positions as per design. |

| Pile Installation | Install piles (driven, bored, or screw). |

| Pile Head Trimming | Remove weak concrete for strong bonding. |

| Pile Cap Casting | Join all piles together with RCC cap. |

| Testing | Join all piles together with an RCC cap. |

| Curing | Ensure durability and full strength. |

Applications of Pile Foundation

Pile foundations are used where surface soil is weak, compressible, or waterlogged and cannot support heavy structural loads. By transferring the load to deeper, stronger strata or rock, piles ensure the strength, durability, and long life of structures. Their applications are extremely wide — from residential houses in weak soils to massive bridges and offshore oil platforms.

Buildings and Skyscrapers

- Where: Multi-storey residential towers, commercial buildings, IT parks, hospitals.

- Why: Heavy vertical loads and weak soil at shallow depth.

- How: Group piles with pile caps transfer loads to deeper strata.

- Example: Burj Khalifa (Dubai) rests on 192 piles, each 50 m deep.

Bridges, Flyovers, and Highways

- Where: Piers and abutments of road and railway bridges.

- Why: To carry heavy loads and resist horizontal forces from traffic, wind, and water flow.

- How: Large diameter bored piles (600–1000 mm) are commonly used.

- Examples in India: Bandra-Worli Sea Link (Mumbai), Ganga Bridge (Patna), Metro viaducts in Delhi and Mumbai.

Marine and Coastal Structures

- Where: Jetties, docks, harbors, offshore oil drilling rigs.

- Why: Piles are essential to withstand water currents, waves, tides, and corrosive seawater.

- How: Steel tubular piles or RCC piles coated with anti-corrosion material.

- Examples: Chennai Port, Jawaharlal Nehru Port (JNPT), Offshore ONGC platforms.

Water Tanks, Silos, and Storage Structures

- Where: Overhead water tanks, grain silos, storage containers.

- Why: Concentrated heavy loads on small footprints.

- How: RCC piles with pile caps spread the concentrated load safely.

- Example: Pile foundations used in municipal water tanks across Indian cities.

Industrial Structures and Power Plants

- Where: Thermal and nuclear power plants, heavy machinery foundations, cooling towers, and chimneys.

- Why: Structures generate dynamic loads (vibrations) and require very strong foundations.

- How: Large groups of RCC piles with raft pile caps.

- Example: Pile foundations in NTPC power plants, Kudankulam nuclear power project.

Transport Projects

- Where: Metro viaducts, elevated highways, railway bridges.

- Why: Safe load transfer for tall piers and vibration resistance.

- How: Large bored cast-in-situ piles (30–40 m deep).

- Example: Delhi Metro, Bangalore Metro, Mumbai Metro.

Retaining Structures and Earth Support

- Where: Deep excavations, river embankments, coastal protection.

- Why: To prevent soil collapse and retain water.

- How: Sheet piles (thin steel/timber sheets) interlocked and driven into soil.

- Example: Sheet pile walls in Kolkata Metro underground stations.

Marine and Offshore Wind Turbines (New Application)

- Where: Offshore wind farms and renewable energy projects.

- Why: Strong lateral forces from waves and wind.

- How: Steel monopiles (up to 10–12 m diameter) fixed deep into the seabed.

- Example: Offshore wind projects on the Gujarat coast.

Special Applications in Residential Houses

- Normally, small houses use shallow foundations.

- But in soft soils, marshy lands, or filled-up areas, piles are required even for G+1 or G+2 houses.

- Screw/helical piles are becoming popular for quick, economical solutions.

Temporary and Emergency Structures

- Used in temporary bridges, military structures, and disaster relief shelters.

- Screw piles can be quickly installed and removed without much disturbance.

So, In Short Applications of Pile Foundation are tabulated below –

| Category | Application Examples |

|---|---|

| Buildings | Skyscrapers, apartments, malls |

| Transport | Bridges, flyovers, highways, metros |

| Marine Works | Jetties, ports, offshore rigs |

| Storage | Water tanks, silos |

| Industrial | Power plants, chimneys, cooling towers |

| Retaining | Sheet pile walls, cofferdams |

| Renewable Energy | Offshore wind turbines |

| Residential | Houses on weak soils |

| Temporary | Military bridges, disaster relief |

Advantages and Disadvantages of Pile Foundation

Every foundation type has its pros and cons. The pile foundation is considered very strong and reliable, especially for weak soils and heavy structures, but it also comes with certain drawbacks. Let’s study them in detail.

Advantages of Pile Foundation

- Suitable for Weak Soils

- When the top soil layers are soft clay, silt, or filled-up land, shallow foundations fail.

- Pile foundations transfer the load to deeper, stronger strata.

- High Load-Carrying Capacity

- Can safely carry very heavy loads of bridges, high-rise buildings, towers, chimneys, and industrial plants.

- A single pile can carry loads of 100–200 tons or even more (depending on type).

- Reduces Settlement

- Uniform load transfer reduces the risk of differential settlement.

- Ensures long-term durability of the structure.

- Versatile in Application

- It can be used for land, coastal, and marine structures.

- Effective for foundations in water (river, sea, ports).

- Resists Lateral Forces

- Provides stability against horizontal loads like wind, earthquakes, and water currents.

- Especially useful in tall structures and bridges.

- Can be Installed in Waterlogged Areas

- Piles can be driven or cast even in submerged or marshy areas where other foundations are not possible.

- Long Lifespan (with Proper Material)

- Steel piles with protective coatings or RCC piles with a good concrete mix last for decades.

Disadvantages of Pile Foundation

- High Cost

- Pile foundations are 3–5 times more expensive than shallow foundations.

- Requires heavy machinery and skilled labor.

- Time-Consuming

- Drilling, reinforcement, concreting, and curing take more time compared to shallow foundations.

- Special Equipment Required

- Needs pile driving rigs, rotary rigs, hydraulic hammers, bentonite pumps, etc.

- Not easily available in remote or rural areas.

- Noise and Vibrations (Driven Piles)

- Driving precast piles creates loud noise and ground vibrations, disturbing nearby structures and residents.

- Difficult to Inspect After Construction

- Once piles are underground, it is hard to check their actual condition.

- Defects can only be detected with special tests (like a pile integrity test).

- Skilled Supervision Needed

- Incorrect pile length, poor concreting, or wrong reinforcement placement can lead to failure.

- Not Economical for Light Structures

- For small houses on good soil, pile foundations are overdesigned and wasteful.

Comparison Between Advantages And Disadvantages of Pile Foundation

| Aspect | Advantage | Disadvantage |

|---|---|---|

| Soil Condition | Works in weak soils and waterlogged areas | Overkill for strong soils |

| Load Capacity | Carries very heavy loads | Costly for small structures |

| Durability | Long life if constructed properly | Difficult to inspect once underground |

| Construction | Can be used in any site condition | Requires special machinery and expertise |

| Environment | Stable against wind, water, earthquake forces | Driven piles cause noise and vibrations |

Read more Civil Engg topics

- Chlorination of water

- Difference between bitumen and tar

- Pile foundation

- Drip Irrigation

- Viscosity

- Surface Tension

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Cement

Conclusion

The pile foundation is one of the most important deep foundation systems in civil engineering. It is specially designed to carry heavy loads and transfer them safely to deeper and stronger soil or rock layers. Unlike shallow foundations, piles make it possible to construct tall buildings, bridges, towers, and marine structures even in weak or waterlogged soils

In this Ultimate Guide, we explored everything about pile foundations, from definition, types, and components to pile caps, construction process, cost in India, advantages, disadvantages, common mistakes, and applications. We also answered the most frequently asked questions that students, engineers, and professionals often search for pile foundations.

Though costly and time-consuming, pile foundations provide safety, durability, and stability that no other foundation type can offer. For large projects or weak soil conditions, pile foundations are not just a choice — they are a necessity.

FAQs on Pile Foundation

What is a pile foundation?

A deep foundation that transfers load to stronger soil or rock at deeper levels.

Which type of pile is most common in India?

Bored cast-in-situ concrete piles are most widely used.

What is the function of a pile cap?

To connect piles and distribute loads equally.

What are the advantages of pile foundations?

Suitable for weak soils, heavy loads, and marine works, and ensures stability.

What are the disadvantages of pile foundations?

Costly, time-consuming, needs heavy machinery and skilled labor.

When is a pile foundation preferred?

In weak soil, waterlogged areas, or for heavy-load structures like bridges and towers.

How long does a pile foundation take to construct?

RCC piles last 75–100 years, steel piles 50–75 years (with protection).

Can pile foundations be used for houses?

Yes, but only in weak or marshy soils; otherwise, shallow foundations are en

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Pile Foundation in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀