Introduction

Portland Cement is the most widely used type of cement in modern construction. According to wikipedia portland cement was invented by Joseph Aspdin in 1824 in England and named “Portland” because, when hardened, it resembled the natural Portland stone found on the Isle of Portland.

Portland Cement acts as the primary binding material in concrete and mortar, which are essential for constructing houses, bridges, roads, dams, water tanks, and many other civil engineering structures. It is widely preferred because of its reliable strength, durability, and relatively fast setting time.

👉 In this article, we will explore the composition, manufacturing process, properties, advantages, disadvantages, applications, and frequently asked questions about Portland Cement.

Note: If you are new to cement, you can first read our detailed post on What is Cement and Components of Cement to understand the basics before exploring Portland Cement.

This article will help students and professionals understand why it remains one of the most important materials in modern construction.

So, let’s get started!

Composition of Portland Cement

Portland Cement is made by blending two main types of raw materials:

- Calcareous materials: mainly limestone, which supplies lime (CaO)

- Argillaceous materials: such as clay or shale, which supply silica (SiO₂), alumina (Al₂O₃), and iron oxide (Fe₂O₃)

👉 In a typical raw mix for Ordinary Portland Cement, the ratio of calcareous to argillaceous materials is about 3 : 1 by weight (roughly 75–80% calcareous and 20–25% argillaceous). This proportion provides the right balance of lime and other oxides needed to form strong cement compounds.

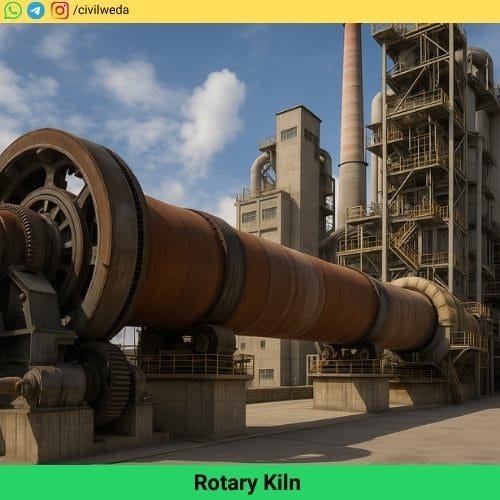

The blended raw mix is burned in a rotary kiln at a very high temperature to form a clinker. After burning, the clinker is cooled and then ground very finely along with about 3–5% gypsum by weight.

👉 The gypsum is added during the grinding stage to control the setting time of cement and to prevent flash setting.

Chemical composition of Ordinary Portland Cement (OPC) is as follows:

| Ingredient | Typical % by Weight | What It Does in Cement |

|---|---|---|

| Lime (CaO) | 60 – 65% | The backbone of cement. Reacts with silica and alumina to form hard compounds that give strength. |

| Silica (SiO₂) | 17 – 25% | Makes the cement harder and improves its long-term strength. |

| Alumina (Al₂O₃) | 3 – 8% | Lowers the burning temperature and helps the cement set a bit faster. |

| Iron Oxide (Fe₂O₃) | 0.5 – 6% | Combines with lime and alumina, adds strength, and gives the typical grey colour. |

| Magnesia (MgO) | 0.5 – 4% | Improves strength in small amounts but can cause cracks if it’s too high. |

| Sulphur Trioxide (SO₃) | 1 – 3% | Comes partly from gypsum; helps in regulating the setting time. |

| Gypsum (CaSO₄·2H₂O) | 3 – 5% | Added during the final grinding stage to slow down the setting time and prevent flash-setting. |

Bogue’s Compounds Formed in Portland Cement

When the raw mix of limestone and clay is burned in the kiln, the oxides combine to form four main compounds, collectively known as Bogue’s Compounds. These compounds control how the cement sets, hardens, and develops strength. These compounds control how the cement sets, hardens, and develops strength.

There are four main Bogue’s Compounds listed in the table below.

| Compound (Bogue’s Compound) | Chemical Formula | % in OPC | Function |

|---|---|---|---|

| Tricalcium Silicate (C₃S) | 3CaO·SiO₂ | 45 – 60% | Reacts quickly with water and gives early strength (first few weeks). |

| Dicalcium Silicate (C₂S) | 2CaO·SiO₂ | 15 – 30% | Reacts slowly but improves long-term strength and overall durability. |

| Tricalcium Aluminate (C₃A) | 3CaO·Al₂O₃ | 6 – 12% | Reacts very fast with water, helps in initial setting. Too much can cause undesirable rapid setting. |

| Tetracalcium Aluminoferrite (C₄AF) | 4CaO·Al₂O₃·Fe₂O₃ | 6 – 10% | Contributes to the grey colour of cement and provides moderate strength. |

Manufacturing of Portland Cement

Portland Cement is manufactured in a well-controlled industrial process in which natural raw materials are transformed into a fine grey powder. The main raw materials are:

- Limestone or chalk (calcareous compound) – provides lime (CaO)

- Clay or shale (argillaceous compound) – provides silica (SiO₂), alumina (Al₂O₃), and iron oxide (Fe₂O₃)

👉 The usual raw-mix ratio of calcareous to argillaceous materials is about 3:1 by weight.

Note Point:

- Temperature in the burning zone of the rotary kiln: 1400 – 1500 °C.

- Lime, silica, alumina, and iron oxide react in this zone to produce clinker.

- Rapid cooling of clinker is important to retain high-strength phases such as C₃S.

- 3–5 % gypsum in the final grinding step is critical to regulate the setting behaviour of cement.

- The dry process is preferred worldwide because it saves energy and produces more uniform cement.

Types of Manufacturing Processes

There are two basic methods for preparing the raw mix before burning:

Wet Process

- Raw materials are mixed with water to form a slurry (30–40 % water content).

- Requires more fuel to evaporate the water → less energy-efficient.

- Used rarely today; still found in a few older plants.

Dry Process

- Raw materials are dried, ground, and blended in dry form before being fed into the kiln.

- More economical and energy-efficient, hence adopted in almost all modern cement industries.

The Step-Step manufacturing process of Portland Cement is shown in the table below:

| Step | Function |

|---|---|

| 1. Crushing and Grinding | Limestone and clay are crushed and ground into fine particles to ensure uniform mixing. |

| 2. Proportioning and Blending | The raw powders are proportioned and blended to obtain the correct chemical composition. Modern plants use automatic weigh-feeders and silos for this step. |

| 3. Feeding to Rotary Kiln | Inside the kiln, the temperature gradually rises to about 1400 – 1500 °C. At this temperature, lime, silica, alumina, and iron oxide react to form Bogue’s Compounds. The semi-molten nodules discharged from the kiln are called clinker. |

| 4. Heating and Clinker Formation | Inside the kiln, the temperature gradually rises to about 1400 – 1500 °C. At this temperature, lime, silica, alumina and iron oxide react to form Bogue’s Compounds. The semi-molten nodules discharged from the kiln are called clinker. |

| 5. Clinker Cooling | The hot clinker is cooled rapidly in air-quenching or grate coolers. Quick cooling preserves the desired compounds and improves grindability. |

| 6. Grinding with Gypsum | The cooled clinker is ground in ball or roller mills. About 3 – 5 % gypsum (CaSO₄·2H₂O) is added at this stage to control the setting time and prevent flash-setting. |

| 7. Packing and Storage | The finished cement is packed in 50 kg bags or stored in bulk silos in dry conditions before distribution. |

Properties of Portland Cement

The quality and performance of Portland Cement are determined by its physical properties and chemical composition. Engineers and builders evaluate these properties to ensure the cement will produce strong, durable, and workable concrete for different construction needs.

1. Physical Properties of Portland Cement

| Property | Value / Range (As per IS standards) | Importance |

|---|---|---|

| Fineness | ≥ 225 m²/kg (OPC 33) 300–350 m²/kg for higher grades | Finer particles hydrate faster → increases early strength. |

| Specific Gravity | ≈ 3.15 | Needed for mix design and batching. |

| Standard Consistency | 25–30% of water by weight of cement | Ensures proper workability and is used in other cement tests. |

| Setting Time | Initial set: ≥ 30 min Final set: ≤ 600 min | Provides adequate time for mixing, placing, and finishing concrete. |

| Soundness | Expansion ≤ 10 mm (Le-Chatelier) or 0.8% (Autoclave) | Prevents cracks due to later expansion. |

| Compressive Strength | OPC (IS 269): 3 days ≥ 16 MPa 7 days ≥ 22 MPa 28 days ≥ 33 MPa (OPC 33) / 43 MPa (OPC 43) / 53 MPa (OPC 53) | The most important structural property. |

| Heat of Hydration | ≈ 80–90 cal/g in first 7 days | Important in mass concrete works (e.g., dams). |

| Colour | Grey (due to iron compounds); white cement is low in iron | Used in decorative finishes. |

| Bulk Density | Loose ≈ 1100–1300 kg/m³ Compacted ≈ 1500–1700 kg/m³ | Helps in estimating storage, transport, and batching requirements. |

2. Chemical Properties

| Property / Ratio | Standard Range | Importance |

|---|---|---|

| Lime Saturation Factor (LSF) | 0.66 – 1.02 | Correct balance of lime → too high → unsound cement; too low → low strength. |

| Silica Modulus (SM) | 2.0 – 3.0 | Affects strength development and clinker formation. |

| Alumina–Iron Ratio (A/F) | 0.66 – 1.25 | Controls formation of C₃A & C₄AF → affects setting and heat generation. |

| Insoluble Residue | ≤ 2% | Unreactive impurities → reduce strength if excessive. |

| Loss on Ignition (LOI) | ≤ 5% | Indicates moisture & CO₂ lost → high LOI means deteriorated cement. |

| Sulphur Content (as SO₃) | 1–3% | Regulates setting with gypsum; excess causes expansion. |

| Chloride Content | ≤ 0.1% | High chloride promotes steel reinforcement corrosion. |

Advantages of Portland Cement

- High early compressive strength → suitable for structural works.

- Good durability in normal conditions.

- Fast setting & hardening → speeds up construction.

- Versatile → used in concrete, mortar, plaster, and precast products.

- Easily available & economical → produced worldwide under standard quality control.

- Compatible with steel reinforcement and supplementary materials.

Disadvantages of Portland Cement

- Generates high heat of hydration → not ideal for massive pours (like dams).

- Moderate resistance to sulphate and acidic environments.

- Carbon-intensive production → contributes to greenhouse gas emissions.

- May undergo shrinkage and cracking if not properly cured.

- Requires adequate curing to achieve design strength and durability.

Applications or Uses of Portland Cement

| Application Area | How It Is Used |

|---|---|

| Building Construction | Concrete for foundations, slabs, beams, columns; mortar for brickwork and plastering. |

| Pavements and Roads | Structural concrete for decks, piers, and abutments. |

| Bridges and Flyovers | Concrete for dams, reservoirs, and water tanks (low-heat cement often used for massive pours). |

| Dams and Water Tanks | Used in normal conditions; in aggressive saline exposure, special cements are preferred. |

| Precast Products | Pipes, poles, blocks, tiles, sleepers, kerbstones. |

| Masonry & Plastering | Mortar for brick/block walls and plaster finishes. |

| Marine Structures | Grouting, crack repair, and patching. |

| Repair Works | Grouting, crack repair, patching. |

| Decorative Works | White Portland Cement for terrazzo, wall finishes, sculptures. |

Note Points

- Portland Cement is suitable for most general construction purposes.

- For special conditions like marine works, dams, and chemical industries, it is often mixed with other materials or replaced by special cements.

- Proper mix design, curing, and quality control ensure maximum performance in all these applications.

Read more Civil Engg topics

- Chlorination of water

- Per Capita Water Demand

- Pile foundation

- Drip Irrigation

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Bitumen concrete

Conclusion

Portland Cement has remained the foundation of modern construction for nearly two centuries. Its balanced composition, reliable strength, and wide availability make it the most commonly used cement worldwide.

From small masonry work to massive structures like bridges, dams, and highways, Portland Cement plays a crucial role. Understanding its composition, Bogue’s compounds, manufacturing process, properties, advantages, and limitations helps engineers and students select the right grade and type of cement for each project.

In today’s world, with increasing focus on sustainability and durability, engineers often use blended cements like PPC, slag-based cements, rapid hardening cement, or low-heat cements in special situations. However, OPC (Ordinary Portland Cement) remains the go-to choice for most general construction projects.

By learning about Portland Cement in detail, future engineers can make informed decisions, ensure better quality control, and contribute to building safe, durable, and sustainable structures.

FAQs on Portland Cement

1. Is Portland Cement the same as Ordinary Cement?

Yes! Ordinary Portland Cement (OPC) refers to the most commonly used type of Portland Cement in construction.

2. Which is cheaper: OPC or PPC?

Generally, PPC is slightly cheaper than OPC because it uses industrial by-products (like fly ash) as a partial replacement of clinker.

3. What is the strongest type of cement?

OPC 53 grade is the strongest, with a compressive strength of 53 MPa at 28 days. For special requirements, High-Strength or High-Performance OPC 53 Cement is used.

4. What is the difference between OPC and PPC?

OPC: Develops higher early strength and sets faster, and good for projects requiring quick progress.

PPC: Gains strength slowly but gives better durability, workability, and resistance to chemical attacks

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Portland Cement in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀