Introduction

Timber is one of the oldest and most important materials used in construction. From ancient houses to modern buildings, timber has always been useful because it is strong, durable, and easy to work with. In simple words, timber means the processed wood that can be used for building and engineering works. It is also known as lumber.

However, it also has some problems. It can catch fire easily, get damaged by insects, and sometimes develop defects. That is why it needs proper treatment and preservation.

In construction, it is used for many purposes such as beams, roofs, doors, windows, flooring, and furniture. It is also used in bridges and other structural works. The main reason for its popularity is that it is natural, renewable, and attractive in appearance.

In this guide, we will discuss the meaning, types, uses, advantages, benefits, and common problems in detail.

What is Timbers?

This is the processed form of wood that is suitable for construction and engineering works. In simple words, timber means the wood that has been cut, seasoned, and prepared for use in building or carpentry. When wood is freshly obtained from trees, it is called a log. After cutting, drying, and treating, this log becomes timbers.

When wood is freshly obtained from a tree, it is called raw wood or a log. This raw wood usually contains a lot of moisture, which makes it weak and prone to decay. To make it strong and durable, the wood is seasoned (dried), cut into required shapes, and sometimes chemically treated. After this process, the prepared material is known as timber.

A common confusion arises between the words wood and timbers:

- Wood: It is a natural material taken directly from a tree.

- Timbers: It is the prepared and treated wood that is ready for construction or carpentry.

This processed wood is widely used in civil engineering because it is light in weight, strong for its size, easy to cut and shape, renewable, and has a natural appearance. Due to these qualities, timber is still one of the most important traditional building materials, even with the availability of steel and concrete.

Sources of Timber:

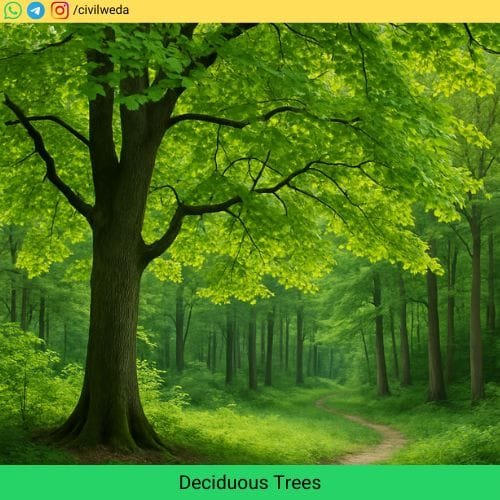

This comes from two major groups of trees, one is Deciduous Trees (Hardwood Trees) and another is Coniferous Trees (Softwood Trees). The properties of timber depend largely on the type of tree it is taken from.

1. Deciduous Trees (Hardwood Trees)

Deciduous trees are those that shed their leaves once a year, usually in autumn or the dry season.

Because they grow slowly, the wood they produce is dense, heavy, and strong, which is why it is called hardwood. Don’t miss our post on Bitumen in Details.

- Grows mostly in tropical and temperate regions.

- Close-grained and dense wood makes it more durable.

- Usually darker in colour with attractive natural patterns.

- Resistant to wear, making it ideal for structures that need strength and long life.

Examples of Deciduous Trees:

- Teak: Highly durable and resistant to decay; widely used for doors, windows, and outdoor furniture.

- Oak: Very strong and hard; used for beams, flooring, and high-quality furniture.

- Mahogany: Smooth texture and rich colour; popular for decorative furniture and cabinets.

- Sal: Tough and termite-resistant; often used for door frames, beams, and heavy construction.

Uses:

- Beams, columns, and flooring in construction.

- High-quality furniture, cabinets, doors, and windows.

- Marine works and outdoor applications (especially teak, because it resists water).

Coniferous Trees (Softwood Trees)

Coniferous trees are evergreen – they keep their leaves (needle-like foliage) all year round.

They grow relatively faster, so their wood is lighter, softer, and easier to cut and shape compared to hardwood.

Key Features:

- Usually grow in cold and mountainous regions.

- Wood is light in colour and less dense.

- Easy to saw, plane, and join, making it suitable for large-scale construction.

- Less durable than hardwood and often needs chemical treatment to resist pests and decay.

Examples of Coniferous Trees:

- Pine: Lightweight and easy to work with; widely used for paneling, furniture, and doors.

- Cedar: Naturally resistant to decay; used for outdoor furniture, paneling, and roofing.

- Fir: Straight-grained and strong; common in house framing and plywood production.

- Spruce: Light yet strong; often used in masts, panels, and even for making musical instruments.

Uses:

- Roofing materials, beams, trusses, and temporary structures.

- Interior paneling, window frames, and plywood.

- The paper and pulp industry is due to its long fibres.

Types of Timber

Timber is classified in different ways depending on tree type, durability, growth pattern, and its use in construction.

Understanding these types helps engineers, architects, and students choose the right timber for each purpose.

1. Based on the Type of Tree

This is the most basic and important classification.

1. Hardwood Timber (Deciduous Trees)

Hardwood processed wood is obtained from deciduous trees, which shed their leaves once a year.

These trees grow slowly, so their wood is dense, heavy, strong, and long-lasting.

It is often darker in colour and has a rich natural texture. Some of the properties of Hardwood processed wood are listed below:

- Dense and close-grained.

- Resistant to abrasion and long-lasting.

- Suitable for heavy-duty structural work.

- Needs proper seasoning to prevent cracks or warping.

Examples of Hardwood:

- Teak: Strong, durable, and resistant to termites and water.

- Sal: Very tough and good for beams and heavy construction.

- Mahogany: Smooth texture, attractive reddish-brown colour, good for fine furniture.

- Oak: Very hard, good for flooring, doors, and beams.

- Shisham (Indian Rosewood): Strong and decorative, good for furniture.

Uses of Hardwood:

- Beams, posts, and flooring for permanent structures.

- High-quality doors, windows, cabinets, and furniture.

- Marine and outdoor applications where durability is important.

Softwood Timber (from Coniferous Trees)

Softwood Processed wood is obtained from coniferous trees, which remain green throughout the year.

These trees grow faster, so their wood is lightweight, softer, and easier to cut and shape than hardwood.

Softwood usually needs chemical treatment for protection against pests and moisture. Some of the properties of Softwood Processed wood are listed below:

- Light in weight and soft to work with.

- Pale in colour and usually straight-grained.

- Cheaper and available in large sizes.

- Less durable compared to hardwood.

Examples:

- Pine: Easy to cut and widely used for doors, windows, and plywood.

- Fir: Light but strong; good for roof trusses and beams.

- Cedar: Naturally resistant to moisture and decay; ideal for outdoor use.

- Spruce: Light and strong; often used in house framing and paneling.

Uses:

- Roof trusses, beams, and rafters.

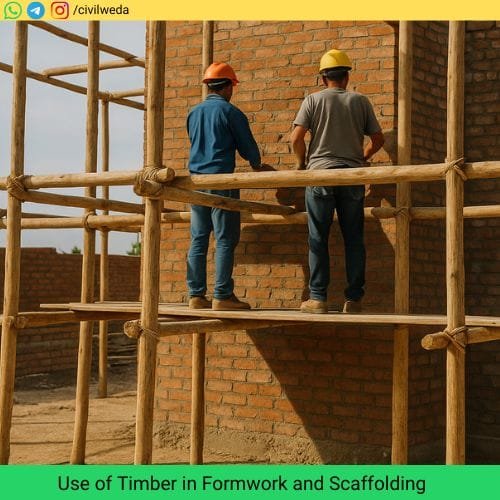

- Temporary structures like scaffolding.

- Plywood, paneling, and wooden packaging.

- Paper and pulp industry (because of long fibres).

Comparison Table:

| Aspect | Hardwood | Softwood |

|---|---|---|

| Source | Deciduous trees | Coniferous trees |

| Growth | Slow | Fast |

| Density & Strength | High | Moderate |

| Durability | High | Medium to Low |

| Ease of Work | Hard to cut and shape | Easy to cut and shape |

| Common Uses | Beams, doors, windows, furniture | Roofing, trusses, paneling, paper |

Based on Durability

Durability refers to the ability of Processed Wood to resist decay, insects, weather effects, and the Seasoning of wooden blocks. Based on durability, it is classified as below:

- Highly Durable (Class I) :

Lasts more than 10–15 years in contact with soil or water.

Examples: Teak, Sal, Oak.

→ Best for beams, sleepers, and marine works. - Moderately Durable (Class II):

Lasts 5–10 years.

Examples: Deodar, Shisham, Mahogany.

→ Suitable for indoor joinery and furniture. - ClaLow Durability (Class III):

Lasts less than 5 years.

Examples: Pine, Mango wood.

→ Used for temporary works, packing, and scaffolding.

Based on the Mode of Growth

How the tree grows also affects the quality of timber.

- Exogenous trees:

Grows outward by adding new layers (annual rings).

Examples: Teak, Sal, Deodar, Pine.

→ This is the most common type used for beams, columns, and furniture. - Endogenous Trees:

Grows inward with intertwined fibres.

Examples: Bamboo, Cane, Palmyra.

→ Not as strong as exogenous timber, but useful for lightweight structures, scaffolding, and mats.

Based on Use in Construction

Depending on the purpose, timber can be classified as:

- Structural Timbers:

Used for load-bearing elements like beams, columns, trusses, and bridge components. - Industrial Timbers:

Processed timber products like plywood, veneers, laminates, and particle boards. - Decorative Timbers:

Used for interior decoration, furniture, carvings, and paneling. - Temporary Timbers:

Used for scaffolding, centering, formwork, and packaging, where long life is not required.

Uses of Timber

Processed wood is one of the most important building materials used since ancient times.

Even today, it is widely used because it is strong, lightweight, easy to shape, and naturally attractive.

Its uses can be classified into structural, non-structural, and special works.

Structural Uses

These are the parts of a structure where timber carries different types of load.

- Beams and Columns:

Hardwood such as Teak and Sal is used in traditional houses, bridges, and small buildings. - Roof Trusses and Rafters:

Softwood timber, such as Pine and Fir, is widely used for trusses, rafters, and purlins because it is light and easy to cut. - Bridges and Decking:

Durable hardwoods such as Teak and Oak are used in bridge decking, sleepers, and other load-bearing works. - Flooring and Joists:

Timber planks and joists are common in wooden houses and heritage buildings. - Formwork and Scaffolding:

Timber is still a popular choice for temporary formwork for concrete casting and for scaffolding because it is light and reusable.

Non-Structural Uses

These parts do not carry major loads but improve the look and utility of a building.

- Doors and Windows:

Teak, Sal, and Shisham are common for strong and durable frames and shutters. - Furniture:

Timber is the main material for chairs, tables, cupboards, beds, and cabinets due to its strength and natural beauty. - Paneling and Interior Decoration:

Decorative hardwoods such as Mahogany and Rosewood are chosen for wall paneling, flooring, ceilings, and carvings. - Partition Walls:

Timber frames and panels are often used for light partition walls in offices and homes. - Roof Shingles and Cladding:

Cedar and other softwoods are used for exterior cladding and roof shingles because they resist weathering.

Uses in Special Case

- Railway Sleepers:

Sal, Teak, and other hardwoods are used for sleepers because they resist vibration and heavy loads. - Marine Works:

Durable hardwoods such as Teak and Oak are used for docks, jetties, boat building, and piles as they resist water and decay. - Bridges in Remote Areas:

Timber bridges are often built in hilly or rural regions because timber is light and easy to transport and assemble. - Packaging and Crates:

Softwood such as Pine is often used for packing boxes, crates, and pallets.

Advantages of Timber

Timber is one of the most trusted materials in construction because it provides many practical and environmental advantages.

Here are the key points:

High Strength-to-Weight Ratio

Processed wood can be lighter than concrete or steel but still strong enough to be used for beams, trusses, and other load-bearing parts can carry good loads without adding much weight to the structure, which makes it suitable for beams, trusses, and floor joists.

Easy to Work

Compared to concrete or steel, processed wood is easy to cut, saw, join, and shape.

Carpenters can make beams, frames, or decorative elements with simple tools.

Durability

High-quality hardwoods such as Teak, Sal, and Oak can last for decades.

If seasoned and treated, this material resists moisture, insects, and fungal decay.

Insulation

Wood is a good thermal insulator.

Buildings made with timber stay cooler in summer and warmer in winter, reducing energy needs.

Aesthetic and Decorative Appeal

The natural grain and colour of wood give interiors a warm, elegant look.

Hardwoods such as Mahogany and Rosewood are often chosen for furniture and paneling.

Eco-Friendly and Renewable

When harvested from managed forests, timber is a renewable resource.

It stores carbon during its life and requires less energy to process than steel or concrete.

Easy to Transport and Assemble

Because it is lighter than many other materials, timber is easy to move and assemble.

This makes it ideal for temporary structures, scaffolding, and work in remote areas.

Sound Absorption

Wood absorbs sound better than metal or concrete.

It is therefore used in auditoriums, studios, and halls to reduce noise and improve acoustics.

Disadvantages / Common Problems of Timber

Although wood is an excellent building material, it also has some limitations and problems that must be understood before using it in construction.

Susceptible to Decay

- If wood is not properly seasoned or stored, it can rot when exposed to moisture for long periods.

- Fungi and mould can damage untreated wood.

Vulnerable to Termites and Insects

- Wood can be attacked by termites, borers, and beetles, especially in damp environments.

- Such infestation reduces strength and durability.

Fire Hazard

- Wood is combustible and burns easily compared to steel or concrete.

- In buildings, it must often be treated with fire-retardant chemicals.

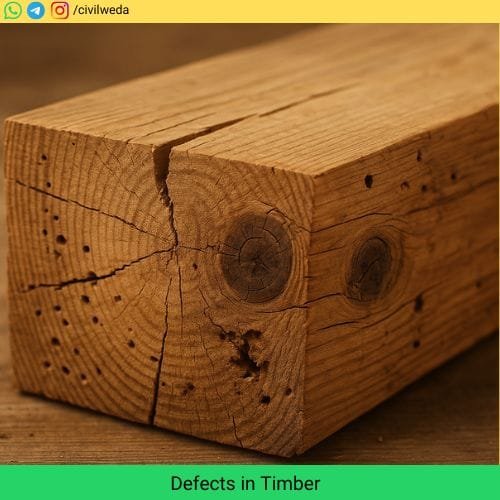

Defects in Natural Wood

Woods may develop defects that reduce their quality:

- Knots: round, hard spots where branches were attached.

- Shakes: cracks or splits that occur during growth or drying.

- Warping & Twisting: distortion due to uneven drying.

- Insect Holes: small cavities caused by pests.

Moisture Sensitivity

- Timber shrinks, swells, or cracks with changes in humidity.

- Requires proper seasoning and protective coatings (like paint or polish).

Limited Span and Load Capacity

- Wooden beams are not as strong as steel or reinforced concrete for very large spans or heavy loads.

- Usually suitable for small- to medium-scale structures.

Requires Regular Maintenance

- To remain durable, wooden structures need periodic polishing, painting, or chemical treatment.

- Neglecting maintenance shortens their life.

Timber Price in India

The price of timber in India varies depending on tree species, quality, size, and region.

It is also influenced by market demand, transport cost, and whether the wood is seasoned or unseasoned.

Factors Affecting Timber Price in India

- Type of wooden block

- Hardwood (e.g. Teak, Sal, Mahogany):

Denser, stronger, more durable → higher price. - Softwood (e.g. Pine, Fir, Cedar):

Lighter, less durable → lower price.

- Hardwood (e.g. Teak, Sal, Mahogany):

- Quality and Grade

- Premium, knot-free, well-seasoned timber is costlier.

- Lower-grade timber with defects is cheaper.

- Size and Thickness

- Larger logs or thick beams are more expensive because they come from mature trees.

- Moisture Content

- Properly seasoned wood costs more than freshly cut (green) timber.

- Region and Availability

- Locally available timber is usually cheaper.

- Imported wood (like Burma Teak, Oak) is more expensive due to shipping and duties.

- Market Demand

- Prices often rise during construction booms or furniture-making seasons.

Tips for Wooden block Buyers

- Prefer seasoned timber for construction → lasts longer and resists decay.

- Always check for defects (like cracks, knots, insect holes) before purchase.

- Buy from trusted suppliers who provide standard sizes and quality certifications.

Read more Civil Engg topics

- Chlorination of water

- Per Capita Water Demand

- Pile foundation

- Drip Irrigation

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Bitumen concrete

Conclusion

Timber has been one of the most important and versatile building materials for centuries.

It is valued for its strength, light weight, ease of workability, natural appearance, and eco-friendly nature.

With proper selection and care, wooden blocks can be used for a wide range of purposes — from structural works such as beams, trusses, and bridges to furniture, doors, windows, and decorative interiors.

However, like any natural material, wooden blocks have some limitations, such as being vulnerable to moisture, insect attacks, fire hazards, and natural defects.

Most of these issues can be controlled by choosing the right type of timber and applying proper seasoning, preservation, and regular maintenance.

Even in the age of steel and concrete, timber continues to be a reliable material for both traditional and modern construction because of its unique combination of strength, beauty, and sustainability

FAQs on Timber

What is timber?

Timber is processed wood that has been cut, dried, and prepared for use in construction, furniture, and other engineering works.

It is stronger and more durable than raw wood because it has been properly seasoned and treated.

2. What is the difference between wood and timber?

Wood: The raw material obtained directly from trees.

Timber: The prepared and usable form of wood suitable for building and carpentry after it has been dried and treated.

3. What are the main types of timber?

Hardwood Timber: From deciduous trees such as Teak, Sal, Mahogany, and Oak → strong and durable.

Softwood Timber: From coniferous trees such as Pine, Fir, Cedar, and Spruce → lightweight and easy to work with.

4. What are the main uses of timber in construction?

Timber is used in beams, columns, trusses, bridges, doors, windows, furniture, flooring, paneling, scaffolding, and railway sleepers.

5. What are the advantages of timber?

Timber is strong, lightweight, easy to work with, naturally insulating, renewable, and aesthetically pleasing.

It is also easier to transport and assemble compared to many other materials.

6. What are the common problems or defects in timber?

Timber can be affected by moisture, insects (like termites), fire, and natural defects such as knots, cracks, and warping.

Proper seasoning, treatment, and maintenance help reduce these problems.

7. Why is timber still used in construction today?

Timber remains popular because it is renewable, versatile, eco-friendly, cost-effective, and provides natural beauty.

When properly treated, it performs well even in modern buildings alongside materials like steel and concrete.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the Timber along with its properties, uses, price in India, and its applications in civil engineering. If you found this guide useful, please share it with your friends and University students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀