Introduction

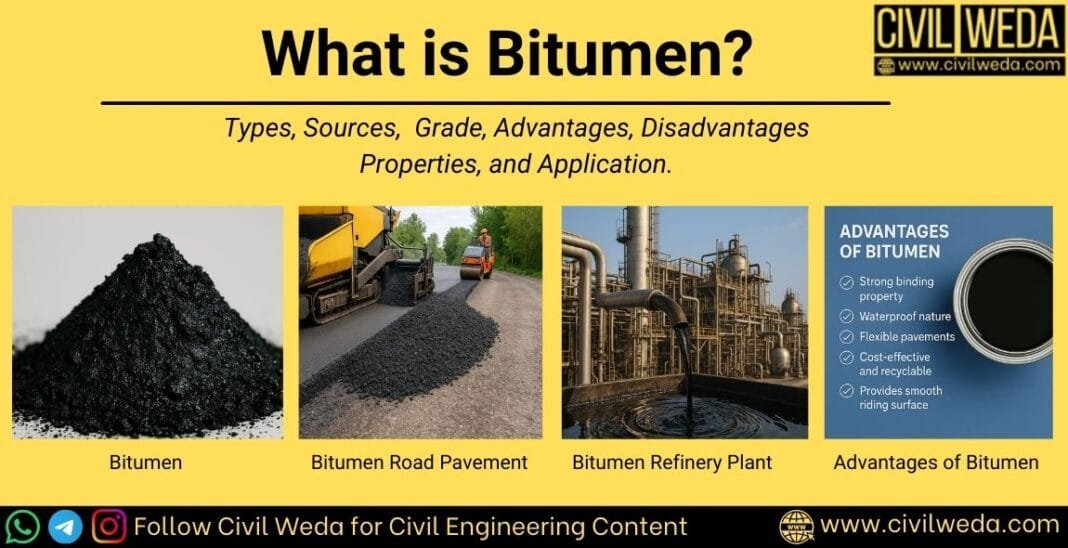

When we talk about road construction or civil engineering works, one common material we hear about What is bitumen? It is one of the most important binding materials used in flexible pavements, roofing, and waterproofing.

Bitumen is a black, sticky, and thick liquid or semi-solid material. It is mainly obtained from the refining of crude oil. Because of its strong binding property, waterproof nature, and durability, it is widely used in civil engineering projects.

In simple words, bitumen works like a glue that binds the stones and sand together to form a smooth and strong road surface. That is why it is the most preferred material for highways, city roads, and even airport runways.

It is important to remember that bitumen, asphalt, and tar are not the same. Asphalt is a mixture of aggregates (stone, sand) and bitumen, while tar is made from coal. This small difference is very important for civil engineering students.

Many beginner students often ask, What is Bitumen? So, in this article, we will study what bitumen is, its types, properties, applications, advantages, and disadvantages. After reading, you will clearly understand why bitumen is called the backbone of road construction in the modern world.

What is Bitumen? Definition and Source

What is Bitumen?

Bitumen is a black, sticky, and highly viscous material that is mainly obtained from the refining of crude oil. During the distillation process of crude petroleum, lighter products like petrol, diesel, and kerosene are separated. After removing these, the heavy residue left behind is called bitumen. This residue has excellent binding and waterproofing properties, which make it very useful in civil engineering.

In simple words, bitumen acts like a strong glue that holds together aggregates such as stone and sand to make roads smooth, durable, and long-lasting.

Chemical Composition of Bitumen –

About 2–8% Oxygen, Sulphur, Nitrogen, and trace metals

About 80–85% Carbon

About 8–12% Hydrogen

Sources of Bitumen

Generally, Bitumens are found from two sources:

Petroleum Bitumen – Produced from crude oil refining, this is the most widely used type in construction.

Natural Bitumen – Found in nature, such as in oil sands and pitch lakes. Though limited, it has been used for thousands of years.

Role of Bitumen in Construction

In simple words, bitumen works like a glue in road construction. It holds together crushed stones and sand, forming a flexible and smooth surface. This is why most highways, city roads, and airport runways are built using bituminous mixes. Unlike concrete pavements, which are rigid, bituminous roads are flexible, cost-effective, and easy to maintain.

Types of Bitumen

To fully understand what is bitumen, we also need to study its different types. Bitumen is not available in just one form; it varies according to its source, refining process, and performance requirements. Each type of bitumen has its own properties and applications in civil engineering.

Based on the Source

Natural Bitumen

- Found in nature, in places like oil sands, tar sands, and pitch lakes.

- Example: Pitch Lake in Trinidad and Tobago and Athabasca oil sands in Canada.

- Natural bitumen is more viscous and sometimes requires heating or dilution before use.

- Historically, it was used for waterproofing boats, buildings, and as mortar by ancient civilizations.

- Nowadays, petroleum-based bitumen has largely replaced it, but natural deposits still exist.

Petroleum Bitumen

- Obtained during the fractional distillation of crude oil.

- After lighter products like petrol, diesel, and kerosene are removed, the heavy residue is processed into petroleum bitumen.

- This is the most commonly used form in modern road construction, roofing, and waterproofing works.

Based on Grade and Processing

Penetration Grade Bitumen

One way to classify bitumen is through the penetration test.

- Classified by the penetration test, which measures how deeply a standard needle penetrates the bitumen sample at 25°C.

- Common grades: 30/40, 60/70, 80/100.Here 30/40 means that penetration value 3 mm to 4 mm

- Lower grade numbers = harder bitumen.

- Example: A 60/70 penetration grade is widely used in India for highway construction.

- Best suited for regions with a moderate climate.

Viscosity Grade Bitumen (VG)

Another classification of what bitumen is based on viscosity

- Introduced to overcome the limitations of penetration grading.

- Classified by viscosity (resistance to flow) at 60°C and 135°C.

- Grades: VG-10, VG-20, VG-30, VG-40.

- VG-10 → cold climates (hilly areas).

- VG-20 → low to moderate traffic roads.

- VG-30 → highways and heavy traffic roads.

- VG-40 → hot climates and industrial areas.

- More reliable because it indicates how the bitumen will perform under traffic and temperature.

Cutback Bitumen

- Produced by adding volatile solvents like kerosene, naphtha, or petrol to bitumen.

- This makes bitumen less viscous, so it can be used without heating.

- Types of Cutback:

- Rapid Curing (RC) → solvent evaporates quickly.

- Medium Curing (MC) → moderate evaporation.

- Slow Curing (SC) → slow evaporation, long working time.

- Applications:

- Surface dressing, prime coat, and patch repairs.

- Drawback: Causes air pollution due to solvent evaporation.

Bitumen Emulsion

- A modern answer to what is bitumen used for in cold conditions is bitumen emulsion.

- Bitumen is dispersed in water with the help of emulsifying agents.

- Appears as a brown liquid.

- Types:

- Cationic emulsion (positive charge) → most widely used, suitable for acidic aggregates.

- Anionic emulsion (negative charge) → suitable for basic aggregates.

- It can be used in wet conditions and does not require heating.

- Applications: cold mix road construction, tack coat, slurry seal, and maintenance works.

- Eco-friendly compared to cutback bitumen.

Polymer Modified Bitumen (PMB)

- Made by blending polymers (like SBS – Styrene Butadiene Styrene, EVA – Ethylene Vinyl Acetate) into bitumen.

- Advantages:

- High elasticity and flexibility.

- Better resistance to temperature variations.

- Longer service life.

- Used in expressways, airports, bridge decks, and heavy traffic roads where performance is critical.

Crumb Rubber Modified Bitumen (CRMB)

- Produced by blending crumb rubber (from waste tyres) with bitumen.

- Advantages:

- Improves resistance to rutting (wheel path depressions) and cracking.

- Withstands high and low temperatures.

- Makes use of waste rubber → eco-friendly solution.

- Commonly used in highways, heavy-duty roads, and areas with extreme climate conditions.

In short, from natural deposits to modern polymer modifications, the types of bitumen explain how versatile this material is. Depending on climate, traffic load, and construction needs, engineers decide the best answer to what is bitumen?

Properties of Bitumen

When we try to understand what is bitumen, it is equally important to study its properties. The performance of bitumen in road construction or any other civil engineering project depends directly on its physical, mechanical, and engineering properties. These properties are usually tested in laboratories to ensure quality before use.

Physical Properties of Bitumen

- Color and Appearance

- Dark brown to black in color.

- Can be in liquid, semi-solid, or solid form depending on grade.

- Density and Specific Gravity

- Density ranges between 1.0 to 1.1 g/cc.

- Knowing density helps in the mix design of asphalt concrete.

- Viscosity

- Bitumen shows high viscosity at room temperature.

- It becomes fluid when heated, making it easy to mix with aggregates.

Mechanical Properties of Bitumen

- Adhesion

- The ability of bitumen to stick to aggregates.

- Good adhesion is important for pavement durability.

- Cohesion

- Internal strength of bitumen that resists flow.

- Helps in providing stability to pavements.

- Durability

- Ability to resist weathering, oxidation, and aging.

- The longer the durability, the better the pavement life.

Engineering Properties of Bitumen

- Penetration Test

- Measures the hardness/softness of bitumen.

- Example: 60/70 penetration grade → medium hardness, commonly used in India.

- Ductility Test

- Measures how much bitumen can stretch before breaking.

- Important for roads in cold regions (resists cracking).

- Softening Point Test

- Determines the temperature at which bitumen starts softening.

- Higher softening point = better resistance in hot climates.

- Flash and Fire Point Test

- Indicates the temperature at which bitumen produces vapors that can catch fire.

- Ensures safe heating during road construction.

- Specific Gravity Test

- Helps in designing bituminous mixes by knowing the weight-volume relationship.

Thus, by studying the properties of bitumen, engineers can decide what bitumen is suitable for different climatic and traffic conditions. And properties of bitumen also give the answer to what is bitumen? For example, in hot regions, harder grades with high softening points are preferred, while in cold regions, ductile grades are used to prevent cracking.

Applications of Bitumen

When we discuss what bitumen is, the next important point is its wide range of applications. Because of its excellent binding, waterproofing, and durable nature, bitumen is one of the most versatile construction materials in civil engineering.

Road Construction

- The most common application of bitumen is in flexible pavements.

- Used as a binder in hot mix asphalt, it holds aggregates together and provides a smooth surface.

- Different grades of bitumen (VG-30, VG-40, PMB, CRMB) are selected depending on climate and traffic load.

- Also used in airfield runways where high strength and smoothness are required. Apart from Bitumen, ready-mixed concrete is also used as pavement material. Don’t forget to read a detailed article on ready mixed concrete.

Roofing and Waterproofing

- Bitumen sheets and coatings are used for roof waterproofing.

- Applied as a damp-proof course (DPC) in buildings to prevent moisture entry.

- Used in underground structures, basements, and tunnels for water protection.

Industrial Uses

- Bitumen is also used in paints, adhesives, and soundproofing materials.

- It acts as an insulating material in industries.

- Used in the manufacturing of bituminous felt for waterproofing.

Miscellaneous Applications

- Protection of pipelines and metal structures from corrosion.

- Used in seal coats, slurry seals, and surface dressing for pavement maintenance.

- Sometimes mixed with polymers or rubber for high-performance projects.

From roads to roofs, the applications of bitumen show how essential this material is in modern construction. By understanding what bitumen is and how it is used, engineers can choose the right type for highways, buildings, or industrial purposes.

Advantages of Bitumen

When students ask what is bitumen? And why it is widely used, the answer lies in its many advantages. Bitumen is preferred over other construction materials like concrete or tar in many civil engineering projects.

- Strong Binding Property

- Works as an excellent binder for aggregates.

- Provides stability and strength to pavements.

- Waterproof Nature

- Naturally resistant to water, making it perfect for roads and damp-proofing works.

- Flexibility

- Unlike concrete, bitumen pavements are flexible and can absorb traffic loads without cracking.

- Cost-Effective

- Cheaper compared to cement concrete roads.

- Easy availability makes it economical.

- Recyclable

- Old bituminous roads can be milled and reused in new pavements.

- Environmentally friendly compared to tar.

- Smooth Riding Surface

- Provides a skid-resistant and noise-free road surface for vehicles.

Thus, by knowing what is bitumen and its advantages, engineers can understand why it remains the backbone of flexible pavements and waterproofing works across the world.

Disadvantages of Bitumen

Although we know what is bitumen and why it is popular in road construction, it also has some disadvantages that must be considered before use.

- Temperature Sensitive

- Becomes soft in hot weather and brittle in very cold climates.

- Performance depends on climate conditions.

- Shorter Life Span

- Compared to cement concrete pavements, bituminous roads need more frequent maintenance.

- Affected by Oil Spills

- Petrol or diesel leakage on roads can damage the surface and reduce its strength.

- Environmental Concerns

- Produces fumes during heating.

- Non-renewable resource since it is derived from petroleum.

So, while understanding what is bitumen, it is important to remember that even though it offers many advantages, its limitations, like temperature sensitivity and maintenance requirements, cannot be ignored.

Read more Civil Engg topics

- Chlorination of water

- Difference between bitumen and tar

- Pile foundation

- Drip Irrigation

- Viscosity

- Surface Tension

- Instrument used in a chain survey

- Fillet Weld

- Bulking of sand

- Bituminous concrete

Conclusion

From this discussion, we clearly understand what is bitumen? and why it is considered the backbone of modern construction. Bitumen is a petroleum-based material with excellent binding, waterproofing, and flexible properties. Its different types, such as penetration grade, viscosity grade, emulsion, PMB, and CRMB, make it suitable for various climatic and traffic conditions.

Although bitumen has some disadvantages like temperature sensitivity and frequent maintenance, its advantages — such as cost-effectiveness, recyclability, and smooth road surface — make it the most preferred material for road construction.

In short, by knowing what bitumen is. Through its types, properties, applications, advantages, and disadvantages, engineers and students can clearly understand its importance in civil engineering and real-world projects.

FAQs on Bitumen

1. What is Bitumen in simple words?

Bitumen is a black, sticky material obtained from crude oil. It acts as a binder in road construction and provides waterproofing in buildings.

2. What is the difference between Bitumen and Asphalt?

Bitumen is the only binding material obtained from petroleum, and Asphalt is a mixture of aggregates (stone, sand, filler) and bitumen, used in flexible pavements.

3. What is Bitumen used for?

The main use of bitumen is in road construction. It is also used in roofing, waterproofing, paints, adhesives, and industrial insulation.

4. What is the Bitumen penetration grade?

Penetration grade indicates the hardness or softness of bitumen. For example:

30/40 → Hard (hot climates)

60/70 → Medium (commonly used in India)

80/100 → Soft (cold climates)

5. What is Bitumen emulsion?

Bitumen emulsion is a mixture of bitumen, water, and emulsifying agents. It can be used in cold conditions without heating and is useful for maintenance work.

Thank You for Reading! 🙏

We hope this article helped you clearly understand the what is bitumen? in civil engineering. If you found this complete article useful, please share it with your friends and university students. For more informative posts on civil engineering topics, stay connected with Civil Weda. 🚀